Electronics manufacturing looks impressive from the outside. However, what if we told you the biggest threats to your process are the ones no one talks about? The ones hiding behind flawless dashboards and ‘on-time’ delivery reports? In such a high-speed industry, success depends on what you catch before it explodes.

In this article, we are going to uncover five uncomfortable truths that quietly wreck projects, inflate budgets, and leave leaders blindsided when it comes to electronic manufacturing.

What is the Electronics Manufacturing Process?

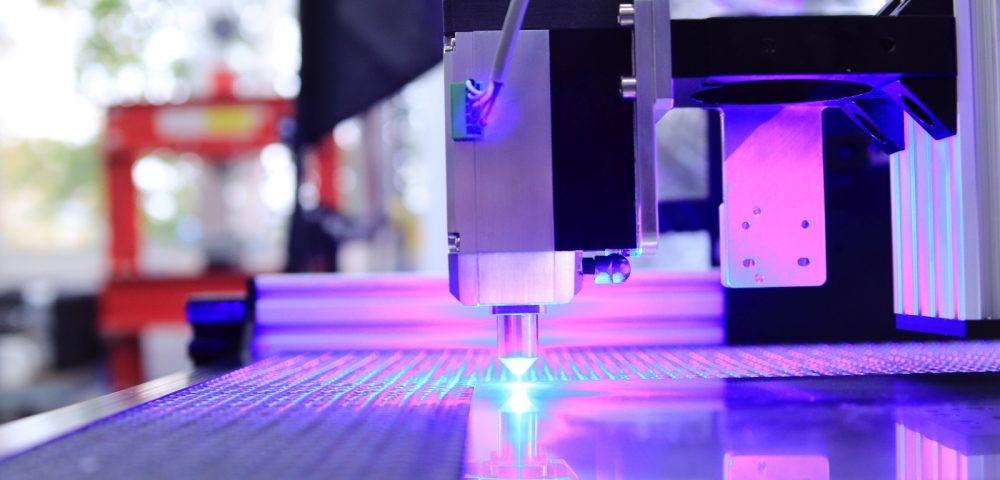

- The electronics manufacturing process begins with designing a product that meets user needs, followed by sourcing the right components like microchips, circuit boards, and wires.

- Manufacturers then move to printed circuit board (PCB) assembly, where machines place tiny parts onto the board with extreme accuracy. After this, they solder the parts to ensure they stay in place during usage.

- Once the board is ready, they test it using different techniques to catch any errors before going further. Then, they assemble the electronics into housings or casings, which could be anything from a smartphone shell to a television body. Technicians check every step to make sure each device works properly before packaging it for shipment.

- This may look simple, yet throughout this process, workers face challenges at every stage.

Top 5 Truths about Electronics Manufacturing

ESG Non-Compliance Can Shut You Down Overnight

Manufacturers who use too much energy, dump toxic waste, or rely on unfair labour end up in headlines for the wrong reasons.

And once that damage hits, fixing your reputation costs more than avoiding the mistake in the first place. Some plants shut down within days after ESG violations because regulators act fast, especially in strict regions. Also, large electronics brands now avoid suppliers who do not meet their clean and fair production standards.

So, every decision, from choosing materials to handling waste, carries weight. This is where the production teams need to stay informed, act responsibly, and follow current ESG rules without excuses.

Most Product Delays Start in the Design Phase, Not the Factory

Engineers sometimes rush to finish product blueprints without thinking about how easily the parts can be built or sourced. Then, as the design passes through each team, confusion starts creeping in. Teams may disagree on specs, struggle to find compatible parts, or overlook key features that affect performance.

These issues stack up fast and push deadlines out of reach. Even the smallest design flaw can slow down testing, cause rework, or make a part fail during assembly. Then you end up wasting days or weeks fixing what you could have caught with better planning.

It is not a secret that many people think the factory causes the delay, but the line just reveals the trouble hiding in the design. So to avoid missed launches and extra costs, designers, engineers, and supply teams need to work together from the start. They need to share feedback, test early prototypes, and double-check every detail before anything hits the floor.

Workforce Skill Gaps Are Wider Than You Think

Skilled workers who understand robotics, automation, and smart systems are now harder to find than the rarest microchip!

At the same time, younger workers usually expect faster promotions or more flexibility, while older workers struggle to keep up with new tools. This growing mismatch creates daily problems on the factory floor, such as machines sitting unused, data getting misread, or updates getting delayed because no one has the right skillset.

There is no doubt that training helps. Still, when time and budgets stay tight, companies fall behind. And once they lose a few experienced technicians, things get worse quickly. Workers start making mistakes, fixing them takes longer, and morale drops.

If they need to close this gap, manufacturers must invest in better training programmes, hire smarter, and create jobs that attract talent across age groups.

Cheap Components Cost You Millions in the Long Run

Let us explain how this occurs. Low-quality parts fail faster, cause customer complaints, and force warranty repairs that cost way more than the savings. Worse, when one faulty component damages an entire circuit board, the whole product turns useless. This not only affects revenue but also damages brand trust.

Once buyers see your devices as unreliable, winning them back becomes nearly impossible. Plus, when quality issues pile up, your team spends more time fixing mistakes than building new features. Production gets messy, suppliers argue, and deadlines slip.

In some cases, recalls become unavoidable, and that is when the losses hit millions. So while saving a few cents per unit may feel safe, those hidden risks grow with every batch.

Choosing reliable parts and testing them well can prevent these problems before they start. Smart manufacturers think beyond price tags and look at how each component performs under pressure.

Fragile Supply Chains

One delayed shipment, one missing chip, or one factory fire in another country can shut down production across multiple regions. Most companies learnt this the hard way during past global crises, when they could not find basic parts even after paying double.

Unfortunately, many factories still rely on just a few suppliers for key materials, and if those suppliers face trouble, there is no quick fix. That kind of risk turns even the best production plans into chaos. This is where the shipping delays, port congestion, trade restrictions, or political tensions make the entire process more unpredictable.

Manufacturers who do not build backup plans or diversify their suppliers often pay a steep price when things go wrong.

Companies that only focus on speed or cost end up exposing themselves to these silent threats. If they wish to handle this better, manufacturers need to track every link in their supply chain, create buffers, and stay ready for change.

Cerexio Track and Trace System for Maximum Transparency

Since it is powered by Industry 4.0 capabilities, by tracking every step in production, Cerexio Track and Trace System uncovers hidden inefficiencies and quality issues in electronics manufacturing. Our system helps reduce rework, exposes supplier delays, ensures regulation compliance, and closes skill gaps with accurate data. Cerexio technology builds confidence in operations and prevents surprises that derail electronics manufacturing.

Staying Away from Avoidable Challenges via Digital Tools

Why battle avoidable challenges when digital tools already hold the answers? From smart planning to real-time alerts, technology transforms headaches into smooth workflows no matter what manufacturing domain you belong to. It is time to get ready to stop guessing and start growing! Your one right footstep will end up becoming your winning game.

FAQ about Electronics Manufacturing Challenges

The most significant trend in the electronics industry is the rapid growth of artificial intelligence integration, driving smarter devices, automation, and innovation while reshaping manufacturing processes and creating demand for advanced semiconductors and edge computing.

The electronic industry plays a vital role in powering digital transformation, enabling smart technologies, supporting communication systems, and driving economic growth. It underpins advancements in healthcare, automotive, manufacturing, and consumer products globally.

Global electronics face major issues, including chip shortages, supply chain disruptions, e-waste challenges, rising production costs, and geopolitical tensions. These factors impact availability, pricing, sustainability, and long-term resilience of electronic product ecosystems.