Cerexio Machine Health Monitoring System

Integration and Automation at Its Best

Cerexio Machine Health Monitoring System, coupled with our instrumentation and PLC (Programmable Logic Controller) services, allows your machine counterparts to be smarter, faster and more efficient. This system offers AI and ML automation, predictive advantages and other digital capabilities to help your machines be operated and managed to increase their useful timelines.

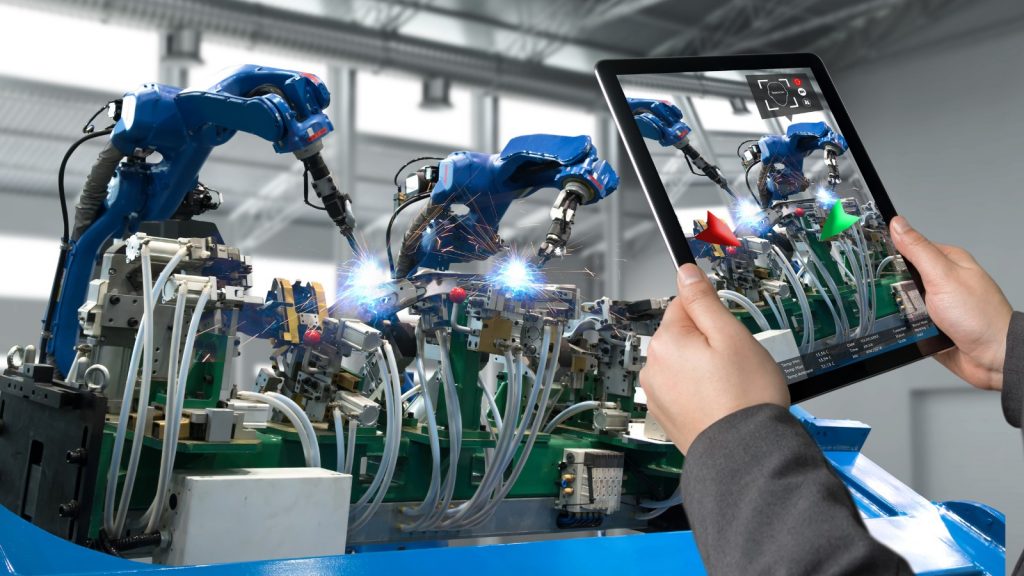

Virtual Interactivity-based Visualisation

View the life cycles of each or all machines by equipping them with simulated environments that help you visit your physical assets through the virtual world. AR/VR technology, Simulative Digital twins and real-time dashboards help your machine service providers understand machine conditions, performance and criticalities inside out.

Unchallenged Analytical Excellence

Cerexio offers 10-year analytical experience powered by AI-based machine analytics, which helps you get comprehensive profiles about future machine performance fluctuations, condition degradation and maintenance budget, keeping your decision-makers informed optimally.

Why do you need the Cerexio Machine Health Monitoring System?

10-year worth of anomaly detection, asset health profiles and compliance reporting keeping you ahead of the curve.

Access to real-time data optimises machine quality management and real-time monitoring through predictive protocols and models

Ensure your asset conditions meet the ISO 55000, ISO 13374 industry standards

Extensive yet scalable machine profiles to identify Remaining Useful Life (RUL) and Reliability-Centred Maintenance (RCM) strategies for better management

Optimise your factories not only be smarter but greener with green manufacturing models integrated into the Cerexio Machine Health Monitoring System

Reliable wireless sensor networks enabled by expert instrumentation services for thermal imaging, vibration Analysis

Stringent authorisation and authentication protocols to keep data phishers and virtual thieves away from your sensitive information.

Plantwide Machine Optimisation in A Single Effort

3D/4D Factory Modelling

This solution offers a simulative platform that helps asset managers to probe, analyse and submit requests without having to be physically present in factories. The digital twin solution we offer makes machine optimisation faster and hassle-free with better visualisation than any other available in the market.

Energy Consumption Monitoring

Cerexio Machine Health Monitoring System allows state-of-the-art green technologies that help you monitor greenhouse gases, compressed air and other parameters that may affect the health of your labourers or the environment. It has machine learning models that ensures overall eco-friendliness.

Robust IT Ecosystem

Cerexio Machine Health Monitoring System can be integrated to your MES, ERP, Asset Maintenance, Project Management System and other IT frameworks to make your asset upheaval procedures meet the best levels. All permitted stakeholders will be updated in real-time all end-to-end asset information.

AI-driven Machine Prognostics

The smart analytical framework of this system filters user-defined information to multiple users based on their dynamic demands. All machine prognostics reports are tailored to the nature of requests, thus saving time in searching and sorting information and jumping straight to final decisions.

ESG-compliant Power Management

Cerexio Machine Health Monitoring System remains at the competitive edge of asset management solutions in the contemporary market for its unique continuous improvement based on recent concerns. This system remains the only one that takes ESG policies, allowing safer, smarter, greener manufacturing.

Smart Machine Calibration

Cerexio Machine Health Monitor excels with Smart Machine Calibration, ensuring optimal performance. Leveraging advanced algorithms, it fine-tunes machines for peak efficiency, enhancing overall reliability and reducing downtime. Upgrade your industrial operations with precision and intelligence.

Cybersecurity At Its Best

The proprietary security protocols incorporated in this system enables futuristic data protection, encryption, privatisation and anti-theft mechanisms to ensure that unpermitted users do not access your sensitive asset and financial information.

Proactive Risk Indicators

This solution is equipped with failure prediction and real-time fault detection technologies powered by AI and ML Failure Mode And Effects Analysis (FMEA) Module. This helps asset manoeuvres detect harmful impacts when utilising or maintaining machines.

Unlimited Sensor Input Channels

Employ IIoT to integrate your sensor data (vibration, force, temperature, Ph Value, RPM, thermocouple, RTS, thermal video and more) into a single, smart system to help you reveal the hidden root causes of machine performance declines and spontaneous breakdowns.

Our Experts Ready to Help You

How does the Cerexio Machine Health Monitoring System improve machine assessment?

Gives users a comprehensive viewpoint that helps them make wise decisions, spot possible areas for development, and carefully schedule maintenance tasks to extend the life of their machines.

Its cutting-edge features meet the requirements of contemporary industrial processes, maximising machine performance through IoT, AI, and predictive and prescriptive analytics to maintain sustainability and competitiveness in an increasingly digitised world.

It makes real-time data analytics possible, giving decision-makers quick insights, identifying possible problems before they become serious, and guaranteeing the effective and continuous operation of industrial assets.

The system's flexibility offers a customised and effective way to improve machine health and overall operational excellence (OEE levels) in a single effort. Thus making assessing budget scenarios fact-based and not periodical.

The system employs artificial intelligence (AI) and advanced analytics to precisely forecast possible problems, facilitating prompt intervention. This accuracy optimises maintenance efforts and reduces downtime, which lowers costs and increases asset reliability.

Benefits of Cerexio Machine Health Monitoring System

5G Technology

Did you know that Cerexio Machine Health Monitoring System is 5G-friendly? It explores the possibilities of 5G technology for faster and more reliable communication, especially in scenarios requiring high-speed data transmission making your analytical experience superfast.

New-age Training

Provides ongoing training and support to users, ensuring they harness the full potential of the system for enhanced machine health management. We will help you up-skill your teams to be more confident when meeting your future goals.

Less Spares, More Uptime

The industry 4.0 features of this system allow your asset managers to meet the best levels of inventory management for the analytical narrations of your machines will help you keep your machines up and running without any spontaneous hindrances.

Rise Throughput & Profit

Cerexio Machine Health Monitoring System increases the output and decreases maintenance costs which ultimately cuts down downtime by keeping an eye on your resources at the same time.

Cloud/ Web or On-Prem

This system utilises cloud-based data storage for scalable and accessible storage solutions, accommodating large volumes of machine health data. However, it can be implemented as an offline on-prem system or we-based system to suit your preferences.

M2M Calls from The Future

Supports a variety of communication protocols, ensuring compatibility with diverse industrial equipment and systems. To elaborate, it can be devised with industry-standard communication protocols like Profibus, OPC, and MQTT for seamless integration with diverse industrial systems.

Remote Machine Statuses

Cerexio Machine Health Monitoring System enables remote monitoring of machines, providing real-time insights into performance and health status. It facilitates remote access and telemetrics to machine data, allowing personnel to make informed decisions regardless of physical location.