Cerexio Predictive Maintenance

Cerexio offers a proprietary Predictive Maintenance Technology that allows asset managers, operators, and planners to employ assets confidently and make smarter decisions Cerexio Predictive Maintenance is a technology suite powered by AI and ML models and predictive technologies trained under realistic operational events and past data records to enable future-proof predictions on asset risk, cost and performance for 10 years ahead.

Decline Maintenance Costs

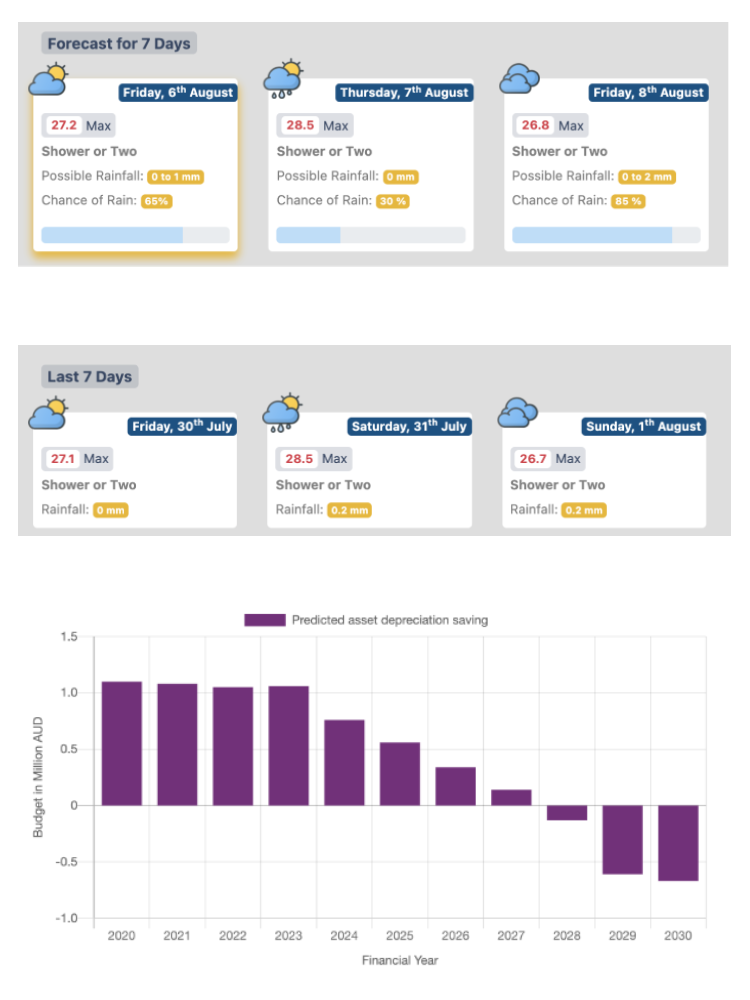

With an overview of the financial viability batches with the asset maintenance costs of your entire asset classes, this solution helps you in cutting down negligible costs and investing in critical asset recoveries in a prioritised manner.

Improved Asset Network Reliability

It can give your asset operators and managers a heads-up on imminent risks, threats and failures of assets; thus increasing the reliability you have on your asset networks.

Industry 4.0 Ready with Digital Twins

Meet all the technology demands of the industry 4.0 definitions. It is powered by Digital Twin, Edge Analytics, IIoT, Big Data Analytics, AR/VR, Simulation and other technologies that define competent asset predictive technologies of the new era.

Why do you need Cerexio’s Predictive Maintenance System?

Are you stressed out with unscheduled system downtimes and skyrocketing asset maintenance costs? Here’s why you should adopt our Predictive Maintenance System.

Machine learning algorithms that are tested, advanced and trained under real-world engineering contexts

Accurately predict the failures, forecast the budgets and prescribe recommendations in a web-based system

Fluidly utilise its models and schemas forever because it inherits the power to augment with next-generation demands

Highly compatible with industry 4.0-defined technologies including digital twin, simulation and AI-driven dashboards

Cerexio Predictive Maintenance is The Leading Benchmark to Mark The Excellence of Asset Predictive Technology

Say no to service shutdown by ensuring that your asset operations are not hindered by unscheduled system breakdowns, prolonged downtimes or spontaneous asset threats with Cerexio’s unrivalled Predictive Maintenance Solution. Strategise your asset maintenance and risk mitigation and recovery plans with the best asset decisions Here are features of this predictive software that can make your asset-oriented industrial establishment powerful and futuristic.

Maximally Trained ML Models

Models power up real-time asset profiles, criticality models, degradation metrics, smart financial dashboards and more since they are optimally trained under noteworthy operational events and historical data that can date back to over 100 years.

Imminent Asset Breakdown Prediction

Cerexio Predictive Maintenance allows an 80+ % reduction in unplanned asset network shutdowns during the first year of solution adoption. It uses optimally trained AI models to predict asset breakdowns saving enough time to mitigate risks.

Completed Asset Data Integration

This solution can flexibly fit in any complicated IT environment to extract data from IIoT systems, ERP, SCADA systems, sensors, databases, and other data points for comprehensive asset insight generation.

Mission-critical Predictive Insights

Based on the unique asset deployment demands of your organisations, you can couple this solution with a simulation platform to gain mission-critical insights on asset behaviours, risks, costs and performance based on certain events.

User-friendly Interfaces

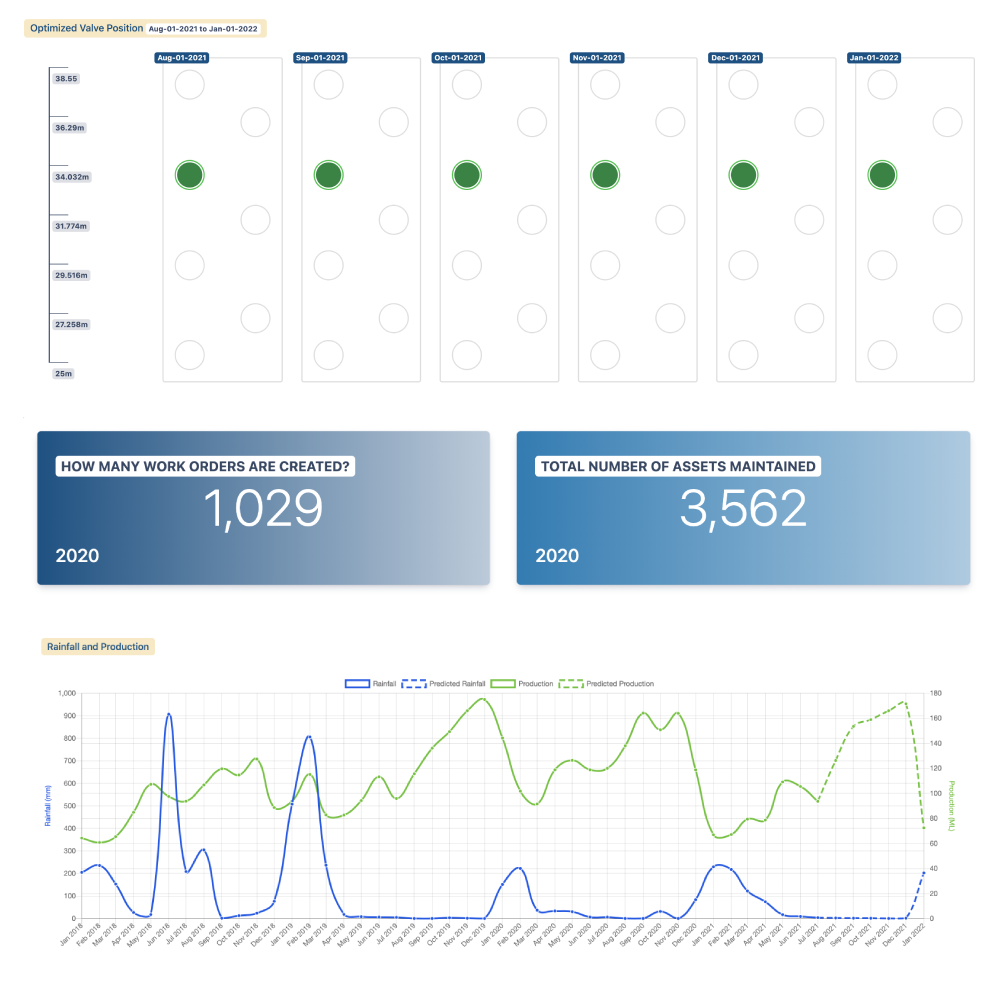

This solution can be equipped via user-defined, mobile-first and frictionless interfaces with interactive visualisation tools like smart and intuitive dashboards, digital twins, GIS layers to ameliorate user experiences.

Selective Analytical Comparisons

Help asset managers understand the integrity of their asset performance. You can compare the service, profitability or activity metrics of your organisation parallel to the performability, reliability and functional metrics of your assets.

Our Experts Ready to Help You

How does Cerexio Predictive Maintenance facilitate your asset decision-making?

Cerexio Predictive Analytics has facilitated many asset-centric organisations across the globe to understand their assets in and out. Since it uses state-of-the-art predictive analytics technologies powered by well-trained AI algorithms, comprehensive index profiles and a range of other technologies, this solution is now the most unrivalled Predictive Maintenance Software.

This Asset Predictive Maintenance Software integrates across the entire stack, so all asset data is being extracted from APM, EAM, ERP, CMMS, Financial Management Systems and other data sources that make this solution the best Asset Maintenance Prediction Solution.

Industry 4.0-defined visualisation tools to present asset insights based on current, future and event-driven situations powered by Digital Twin, AR, VR, GIS Maps, Simulation and more. You can use these tools to manipulate and process asset data efficiently.

The embedded reports and profile generating tools allow asset decision-makers to request, validate and print asset documentation. They are available in both AI-based automatic reports tools and manual user-defined reporting tools as well.

Cerexio Predictive Maintenance enables at-a-glance decision-making to guide data specialists to make improved decisions that lead to better outcomes. This way the firm can optimise operational excellence, asset utilisation and more.

Mitigating risks, frauds and suboptimal asset functionality by betters understanding the management of physical and financial assets to pinpoint internal and external mismanagement of assets by contrasting with predictive maintenance insights

Benefits of Cerexio Predictive Maintenance System

The unapologetic disruptions made by the emergence of new-age technologies allows asset managers to take extra measures in digitising and optimising asset maintenance efforts using industry 4.0 defined technologies. Out of these technologies, one of the most critical technology upgrades is Predictive Maintenance Technologies. Cerexio Predictive Maintenance helps by eliminating risks, threats and suboptimal performance one decision after another. Here are some of the noteworthy advantages of this solution.

Scalable Comprehensive Insights

Understanding the degradation trends, criticalities, the severity of asset environment impacts enabled by the solution will guide you in utilising and augmenting the deployment of assets based on different operational events.

Easy-to-Use Interfaces

This solution offers mobile-first interfaces that are advanced with smart dashboards and can be integrated with interactive visualisation tools like Digital Twin, Simulation, AR, VR and GIS Layers to adopt frictionless software for hands-on asset predictive analytics.

Deep Dive Into Asset Failures

This solution is developed to uncover interdependencies, connections, correlations, hidden causes behind the changes in asset conditional and structural indexes. It allows users to find ways to make faster decisions in ensuring the hi-performance and health of assets.

Minimise Inconveniences and Maximise Opportunities

Cerexio Predictive Maintenance Software minimises three main threats that affect the OEE of your industrial assets, they are prolonged maintenance time, drawn-out system downtime and spare part and asset supply costs. This helps in developing the availability, performance and quality of your assets.

Tenfold Increase in Opportunities

This software system has proven to show huge increases in ROI levels, 30% decreases in negligible maintenance costs with the same asset investment and self-reliance of the user- your organisation can be free from the expensive assistance of experienced technicians or data specialists.

Fluid Work Environments

Your asset teams can work fluidly to meet faster resolutions because the predictive insights generated by this solution can enable full visibility of asset operations and updates to targeted asset stakeholders via cutting-edge tools.