When it comes to controlling industrial processes, we see that SCADA and HMI usually appear side by side. However, in reality, they are far from interchangeable. As an industrialist, how do you know which system suits your setup? Are you missing out by relying on just one? The answer lies in understanding their unique strengths, from local machine control to wide-scale data analysis and remote monitoring. If you want your operations to run smarter and safer, this understanding is a must.

In this article, we cover the key differences between SCADA and HMI.

What is SCADA?

SCADA stands for ‘Supervisory Control and Data Acquisition.’ It works like the brain of industrial systems by helping operators keep track of multiple machines or entire facilities from a central location.

Also, it simply connects to field devices like Programmable Logic Controllers (PLCs) or Remote Terminal Units (RTUs) that gather real-time data from sensors, valves, and motors. That data then flows to SCADA servers, which process and organise it into useful information.

From there, the system sends it to dashboards, displays, or even higher-level business tools, so decision-makers can act fast and with confidence.

The uniqueness of this is that SCADA systems do not just show what is happening now. Instead, they also store and analyse past data, which helps teams spot trends, generate reports, and predict future issues before they grow into problems.

What is HMI?

An HMI, or Human-Machine Interface, acts as the touchscreen or control panel that lets people interact directly with machines or processes on the factory floor.

Operators use it to see what the machine is doing in real time and to make quick changes when needed.

Most HMIs come in the form of industrial touchscreens, mounted near the machine they control, while others come built into devices or run as software on tablets or computers. These interfaces do not manage entire systems. Instead, they focus on one machine or process at a time, keeping things simple and direct.

Through an HMI, operators can adjust temperature, pressure, or speed settings with just a few taps. They also get instant feedback through visualisations like gauges, graphs, or status lights, which makes the system easier to understand.

Difference Between SCADA and HMI

| SCADA | HMI |

|---|---|

| Usually runs on PCs, industrial workstations, or servers. | Generally come as touchscreen panels or compact hardware units with built-in software. |

| Acts as a control layer between the operator and PLCs, offering advanced visualisation and control. | Connects operators to PLCs but focuses on basic tasks and has fewer features. |

| Allows users to monitor and manage operations remotely across different locations. | Mainly used for on-site machine control and monitoring. |

| Can collect, organise, and display large volumes of data from multiple sources. | Can show real-time data but struggles with complex or large-scale data handling. |

| Supports complex logic and can automate control strategies across a network. | Has minimal support for advanced logic or control automation. |

| Can link up with various systems like PLCs and DCS for coordinated control. | Works independently and usually connects to a single system with limited integration. |

| Manages multiple machines and systems spread across different sites using network connectivity. | Works with individual machines or systems located in a single facility. |

| Provides detailed real-time dashboards and long-term data reports. | Shows real-time status in a simple layout, without in-depth reporting tools. |

| Can create alerts and send notifications using different protocols for early action. | Can generate basic alerts but lacks flexible or remote notification options. |

| Stores historical data and logs for extended periods, useful for performance review. | Has limited capacity for saving data or reviewing past operations. |

| Supports advanced trend tracking and allows customised report generation. | Can display trends on a basic level, but cannot create custom reports. |

| Allows batch control and recipe handling for complex production environments. | Offers limited or no support for batch process control. |

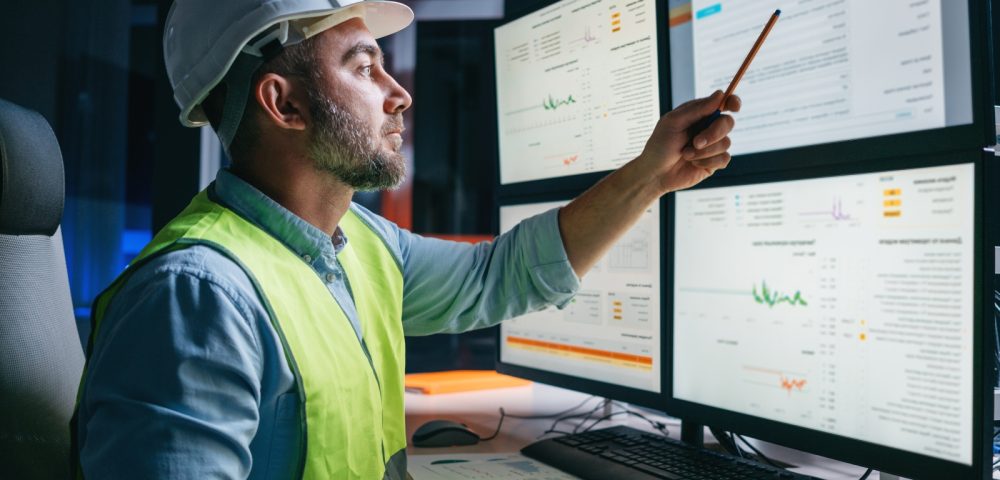

How They Work Together

SCADA and HMI systems usually do not compete with each other. They actually work together to keep industrial operations running smoothly.

It works this way: You can imagine HMI as the machine’s local dashboard, where the operator stands nearby, watches real-time data, and tweaks settings like temperature or pressure on the spot. It acts like the hands-on control point, showing simple visuals, buttons, and alerts directly on a touchscreen or small panel near the machine.

Now add SCADA into the picture, and you get something much bigger. SCADA collects data from many of these HMIs and other field devices, then sends it all to a central server or workstation. From there, operators and engineers get a wide-angle view of everything that is happening across multiple systems, even across different locations.

They can monitor trends, pull up historical records, and spot problems before they get worse.

As you can see, HMIs handle the moment-to-moment interaction, while SCADA connects the dots and turns scattered machine data into meaningful insights.

When to Choose Each

Choosing between SCADA and HMI depends on what kind of control and visibility you actually need.

If you are running a single machine or a small production line and just want basic local control, then going with an HMI makes the most sense. It gives you a simple, cost-effective way to see what is happening in real time and make quick adjustments on the spot. You do not need a full-blown system when one touchscreen panel can do the job.

But when your operations start spreading out, maybe across different buildings or even multiple sites, you need more than just local monitoring. That is where SCADA steps in. It connects everything together, giving you remote access, centralised control, and long-term data analysis that HMI alone cannot offer.

Modern Capabilities

HMI

It is indeed a proud moment for the industrialists to see that HMIs have come a long way from simple touchscreens stuck to factory walls.

Nowadays, operators can access HMIs on mobile devices, giving them the freedom to monitor and control machines from anywhere in the plant or even offsite. This mobile access means faster reactions and more flexible workflows.

Edge HMIs take things further by processing data right where it is generated, reducing delays and helping machines run smoother without waiting for signals to travel far. Some HMIs now even experiment with augmented reality (AR) and virtual reality (VR), letting workers see machine data overlaid on real equipment or explore 3D models, which makes troubleshooting more intuitive and less guesswork.

SCADA

On the SCADA side, the technology is evolving too. Artificial intelligence helps analyse mountains of data to find patterns humans might miss, predicting failures before they happen. Edge computing within SCADA systems speeds up decisions by processing data locally instead of sending everything to a central server. Cloud integration and historian databases let teams store and access vast amounts of operational data anytime, anywhere, helping with long-term planning.

Cerexio Coverage for Full Integration of SCADA and HMI

Cerexio is proud to present our Industry 4.0-driven IoT integration system that works smoothly with virtually any SCADA or HMI setup. Our solution uses flexible, open standards and protocols designed for easy connection. Instead of forcing companies to change their existing systems, Cerexio platform plugs right into the current infrastructure, whether that involves older or newer SCADA and HMI solutions.

Ensuring You Select the Right System at the Right Time

The key to seamless operations starts with choosing the system that matches your unique needs, whether it is a simple local HMI or a sprawling SCADA network. However, you need to consider scale, integration, data flow, remote control, and costs carefully. The right choice you make at the right time saves headaches tomorrow. This might be the first step to empower your team with exactly what they need.

FAQs about SCADA and HMI

Yes, SCADA and HMI normally work together within the same system. HMI provides local machine control and visualisation, while SCADA offers centralised monitoring and data analysis across multiple devices. This enables seamless operation and improved decision-making.

SCADA is a comprehensive monitoring system that supervises industrial processes remotely. It collects real-time data from field devices, displays it on dashboards, manages alarms, and stores historical data for analysis and reporting.

Yes, a PLC can operate independently without HMI or SCADA. PLCs control machines by executing programmed instructions, but without HMI or SCADA, operators lack visual interfaces and centralised monitoring, limiting control and real-time data access.