You simply cannot deny the fact that your manufacturing business runs on the wheels of market demand. Imagine one day you enter a production floor with piled-up orders, but zero material stocks! It is the worst nightmare for the entire manufacturing industry, right? This is why there has been a concept known as ‘demand planning’ in the business scenario. The manufacturers who embrace demand planning strategically will be able to prevent a crisis, as it becomes a lifeline for them.

In this article, we answer the question ‘what is demand planning’ while exploring its importance for the manufacturing industry.

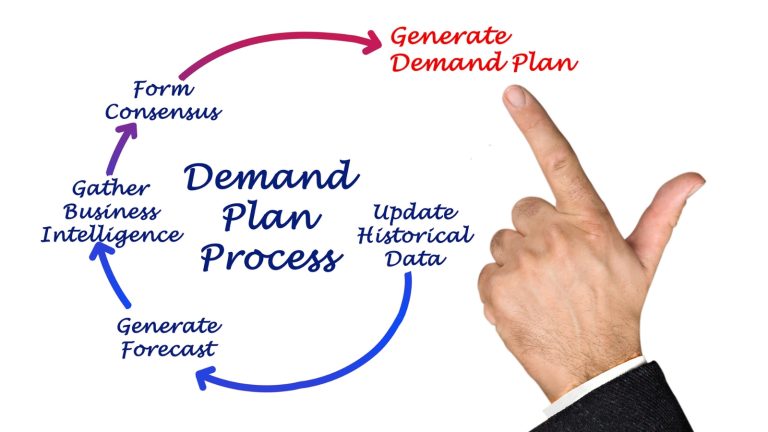

What is a Demand Planning Process?

- The demand planning process is the mechanism which businesses adhere to different forecasting methods to predict the amount of products the customers will demand from the company. The main reason to develop this concept is that businesses, or specifically manufacturers, will be able to estimate in what quantities they will have to plan production in the future. This includes some other important aspects such as inventory, warehousing, packaging, logistics, etc.

- The demand planning is not a singular process, as it consists of several steps. The first layer starts with data collection. Manufacturers need to gather information from their past sales records, how the market trends have varied over the years, and how seasonal patterns have changed. The next stage is forecasting, and this is where they analyse the data they gathered to speculate on the upcoming patterns.

- Next comes the collaboration stage. In this, various departments like production, warehousing and supply chain work closely to share insights. Then we step into the planning phase, where the manufacturers tend to generate a roadmap for the production schedules, inventory levels, and procurement.

- At the final point, manufacturers monitor the results and keep making adjustments, aligning with the market and customer demand changes.

The Importance of Demand Planning for Manufacturing

It Optimises Inventory Levels

Demand planning is important mainly because it is what reveals to the manufacturers exactly how much product has to be produced during a specific period. If the companies go without a methodical formulation of operational frameworks, they may end up generating too much. The result would be unsold stock taking up space and wasted money.

On the other hand, the customers will be disappointed if you have produced too little and if it leads to stockouts unexpectedly. This is why the manufacturers need to pay much attention to accurate demand predictions. That way, they are able to keep the inventory levels at the right quantities. No overstocks and understocks will occur.

Therefore, if reducing waste while saving money is the ultimate goal, the manufacturers pour the cement for that with demand forecasting, as it guarantees smooth operational architecture.

It Improves Production Efficiency

When creating production schedules to align actual market demand, demand planning is the initial point for that. This signifies that receiving accurate information on potential demand fluctuations supports manufacturers in employing labour and machines effectively and efficiently.

If there is no rush for a certain type of product, this removes the necessity of making tight production schedules on the operational floors. Instead, the labour and machines can be used to produce some other type of goods that gain more attention in the market during this period.

Just as overproduction, underproduction is problematic for manufacturers. This means, just as underproduction wastes materials and other resources, overproduction wastes time, money and energy.

When the managers go with demand planning, they inspect the past track records of the same products during the same period and analyse them with the competitors. They foresee the risks ahead, and according to that knowledge, the production can be carried out smoothly.

It Enhances Customer Satisfaction

The primary reason manufacturers engage in demand planning is its ability to meet customer needs on time. The best benefit of such forecasting is that it extends the opportunity for manufacturers to produce goods and make them available to purchase whenever customers need them. If the products are not readily available, stockouts, delays in delivery give wings to unsatisfied customers.

The manufacturing business is all about delivering the right products at the right time. This is how they can build trust and loyalty. Enhanced customer satisfaction is followed by referrals, recommendations and boosted brand reputation, etc.

It Supports Accurate Financial Forecasting

Demand planning not only focuses on one aspect, such as production, but it also provides more vital data for businesses to estimate their potential expenses and expected income for the upcoming period. It is straightforward for them to make estimates of their revenue precisely, rather than going with mere assumptions, when they have a good understanding of what products will sell and when.

Companies are able to plan costs for raw materials, labour, and production more effectively. The prime advantage of accurate financial forecasting is that it simply reduces the risk of overspending or running into shortages. For management pillars like investments, expansion, and budgeting, the authorities can make smart decisions if they attempt demand planning.

As it offers clear indications on what is going on in the upcoming seasons, the managers receive the opportunity to create realistic financial plans aligning with market needs. By removing financial uncertainty, demand planning improves cash flow and ensures that organisational resources are channelled through evidence-based allocation frameworks.

Reduces Operational Costs

Cost reduction is undoubtedly the main goal of any manufacturing organisation. Trying effective demand planning is an outstanding method for manufacturers to take away the burden of unnecessary costs. Imagine the production occurs aligning with the actual demand; This way, companies do not have to put much focus on generating too many products. It will only be a total waste of raw materials and storage space. Demand forecasting removes the burden of urgent last-minute orders, and these do not come inexpensive.

It is not planning just ahead, but it is planning ahead ‘accurately’. Likewise, businesses have enough time to buy materials in bulk at lower prices while scheduling labour efficiently. This not only reduces energy and transportation costs, but also clears the road for less waste and better use of resources. The synergy of all these advantages points in one direction, which is reduced operational costs.

Cerexio Production Order Management System with Accurate Demand Planning

If demand planning is what bothers your manufacturing company the most, Cerexio offers the best solution for that. Cerexio Production Order Management System is driven by Industry 4.0 capabilities such as AI, Predictive Analytics, Digital Twin, etc. to offer you a 360-degree view of market and customer demands based on different seasons. By analysing past data of your sales and product movements, the Cerexio software solution guarantees you are out of danger of wasting money, time and resources.

Embrace Demand Planning for Manufacturing Success

Manufacturing success depends on various factors like customer satisfaction, ROI, sales, quality and all. Not one or a few, but demand planning lays the base for almost all these factors. Why waste money, time, labour and warehousing space when you can predict the demand accurately and do the production based on that? Think a moment!

FAQ about Demand Planning

Imagine you regularly sell 1000 units per month of a specific product. In that case, you have to stick to that number, not producing either 750 or 1200. Demand planning means you analyse how much you produce on a regular basis and keep your production tight on that margin without trying to underproduce or overproduce.

It helps businesses estimate the precise customer demand for products while removing the need for excess inventory and eliminating supply chain disruptions.

AI forecasting models are mainly useful for the supply chain stakeholders who face disruptions as they offer real-time insights into demand, supply and overall market circumstances. With AI integrations, supply chain management receives the opportunity to keep service levels equal even amidst port delays or material shortages, etc.