Manufacturing is one whole domain which consists of different sub-elements. From machinery, collecting materials, processing, and item tracking to distribution, there are many stages. Supply chain management is one such realm; manufacturers have to employ cutting-edge technology and strategies to keep it on point. RFID, or Radio Frequency Identification, is one such technological arm that manufacturers tend to utilise in their supply chain operations.

How exactly can this technique help manufacturers with supply chain management? Let us explain inside our article.

How RFID Technology Works

Before employing this in your manufacturing supply chain framework, you need to have a good understanding of its true essence. You may have been utilising ‘Barcode Technology’ in your operations. RFID is one big step ahead of it!

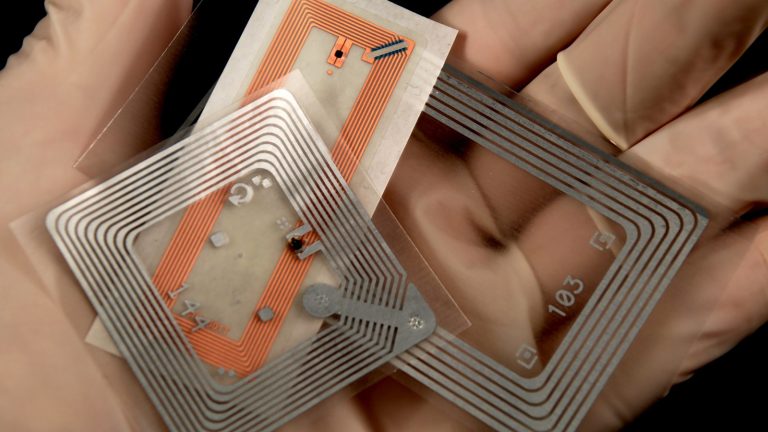

This is a technology that uses radio waves to automatically identify and track objects or people. Let us explain how RFID technology works. It consists of RFID tags attached to the object being tracked, a reader or interrogator that emits radio waves to interact with the tag, and a database system for storing and processing the information gathered. Basically, it has two main components. Those are tags and readers.

RFID tags can be passive, powered by the radio signal from the reader, or active, with their own power source. The latter has been used in a variety of applications ranging from commercial to industrial in today’s tech-driven world.

If we fly back to its history, this has been in the spotlight since the 1970s. However, with the global supply chain management requirements and pet microchipping, RFID receives universal accessibility.

Since then, manufacturers around the globe have tended to utilise them in various applications such as inventory management, access control, supply chain management, and contactless payment systems. It is visible that RFID technology enhances efficiency, accuracy, and automation in tracking and monitoring processes across industries.

Exploring Benefits of RFID in Supply Chain Management

Reducing Chances of Loss and Theft

Inside a manufacturing plant and warehouse facility, there is a high chance of your products getting lost or being robbed by unauthorised groups. This is a rising concern for the plan managers, and they are desperately in need of innovative solutions to this matter.

This is where RFID technology enters into the scenario as a potent tool to prevent such activities inside the plant or warehouse. Now, let us walk you through how it is done. When it comes to RFID technology applications, they reduce the likelihood of loss and theft by offering continuous, real-time visibility and control over inventory and assets owned by your company.

Did you know that RFID has the ability to tag items with unique identifiers and integrate RFID readers? Yes, this occurs throughout the entire supply chain. Through the synchronisation of Blockchain and RFID technologies, manufacturers can monitor the movement of goods from production to distribution. Any unauthorised or anomalous activity makes the way for the system to trigger immediate alerts. This is one of the main advantages of RFID technology, as it encourages quick actions.

As you can see, this heightened transparency is a great path to ensure a theft-free zone inside your plant. Plus, it also ensures accurate tracking, minimising the chances of misplaced or stolen items. On the other hand, you have RFID technology for events, which means you are well-equipped to reduce the risk of stockouts and shrinkage.

RFID’s ability to provide comprehensive monitoring and rapid response mechanisms strengthens security measures, which leads to revolutionising the entire inventory management with ease.

Enhancing Visibility with RFID Tags

In this particular section, we are focusing on the advantages of using RFID tags over traditional barcode technology. Unlike this old strategy, RFID tag technology enhances visibility within the manufacturing supply chain by enabling real-time tracking and monitoring of assets, inventory, and processes.

The way it is done is simple to understand. These tags attached to items transmit data wirelessly to RFID readers. This transmission provides accurate and instantaneous information about their location, status, and movement. Since your company is thorough with the latest occurrences within your supply chain, this visibility allows manufacturers to optimise operations accordingly. Plus, it helps you predict some bottlenecks and improve decision-making in the end.

Yes, as we mentioned before, this tracks assets and can also trace the process movements. It is like having a comprehensive view of the supply chain activities under one canopy. This way, manufacturers can identify inefficiencies, streamline workflows, and proactively address issues such as delays or miscommunications among the departments.

With RFID in logistics and supply chain operations, you can make sure the stakeholders have access to the latest data about products and their movements. In one way, it boosts transparency between the companies and clients. In another way

The latter offers you with greater levels of efficiency.

Higher Levels of Accuracy in Product Picking

Product picking is one aspect that often goes wrong within the manufacturing plants with traditional picking methods. But if you have RFID tag technology, it can provide precise, real-time identification and tracking of items, which will lead to 100% accuracy rates for sure.

RFID tags embedded in products or packaging contain unique identifiers that are automatically scanned by RFID readers as they move through the picking process. This automated system helps prevent unwanted human error associated with manual barcode scanning or paper-based systems. There is no need to say that it comes out with great capabilities for product selection.

With RFID, workers can quickly locate and verify the correct items. This significantly reduces picking errors, misplacements, and mix-ups. On the other hand, RFID has flawless integration abilities with inventory management systems, allowing for immediate updates on stock levels and restocking requirements.

It is a clear fact that companies that use RFID technology have outstanding records of picking operations, as the latter enhances order fulfilment efficiency and boosts overall customer satisfaction within the manufacturing supply chain.

Boosting Productivity

RFID in the supply chain serves as an ‘all-in-one’ tool for productivity enhancement across the entire manufacturing supply chain cycle.

As we stated before, it helps automate processes such as inventory management, asset tracking, and order fulfilment. This means it helps reduce manual labour requirements and minimises errors, leading to streamlined operations and increased efficiency.

One of the main benefits of RFID in supply chain management is that it facilitates seamless coordination between different stages of the supply chain. This act backs up smoother logistics operations and faster turnaround times. With improved productivity at each step, from production to distribution, RFID technology ultimately drives down costs and accelerates throughput. This is the way to expedite the overall performance of the supply chain framework.

Cerexio Technologies for a Better Supply Chain Management

Industry 4.0 digital capabilities power Cerexio technologies; they have high levels of integration capacity. RFID technology is one tool that can be flawlessly integrated into our solutions and shaped upon your industry-specific requirements. With Cerexio power in place, your manufacturing operational ecosystem is surely on point!

Magnifying Supply Chain Visibility with RFID Technology

Walking away from traditional methods, manufacturers can achieve their business goals so that each interwoven chain of the business is shaped perfectly using new tools. RFID technology in supply chain management is something you should keep in touch with if you target a top spot in the market.