Are you worried about the rising temperature inside your factories, warehouses, and industrial workshops? The good thing is that in warehouses and factories, heavy-duty industrial fans can make the environment feel 6–10°F (3–6°C) cooler by enhancing airflow. These rugged machines move more than air; they drive comfort, safety, and efficiency where it matters most. However, the real problem pops up when industrialists pick the wrong fan and pay the price in energy, noise, and frustration.

This article breaks down the key factors you need to consider when selecting the best heavy-duty industrial fan.

We will look into

Why Choosing the Right Industrial Fan Matters

- This is mainly because it directly shapes how effectively a workspace stays comfortable, safe, and efficient.

- A properly selected fan pushes enough air to improve ventilation, removing heat, dust, and fumes while keeping fresh air moving across every corner. This steady airflow makes workers feel cooler, breathe easier, and stay focused without battling stifling conditions.

- Good fans also help lower energy bills since they do not waste power struggling to move air in the wrong direction or at the wrong speed.

- They even protect equipment and building structures by keeping moisture, debris, and stagnant air from causing rust or wear.

Types of Heavy-Duty Industrial Fans

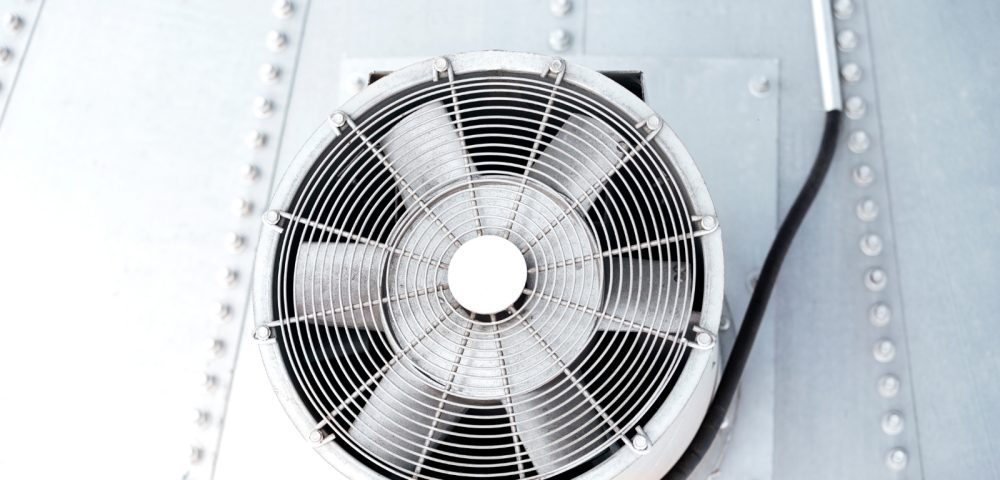

Axial Fans

Axial fans use a propeller-style design to move large volumes of air at low pressure. They work great in open spaces like factories, warehouses, or workshops where you need to keep air circulating freely. Industrialists choose them because they handle heat, dust, and fumes well without taking up much space.

Centrifugal Fans

These are usually called blowers, and they push air through ducts with high pressure. You will find them in HVAC systems, clean rooms, or spray booths where air needs to move forcefully through filters or vents.

HVLS (High Volume Low Speed) Ceiling Fans

HVLS ceiling fans spin slowly yet move massive amounts of air gently across wide areas. They suit large, open spaces like gymnasiums, warehouses, and barns where you want to keep air fresh without creating a draft. They reduce stuffiness and help cool spaces efficiently and quietly.

Portable and Fixed Fans

Portable fans let you move them anywhere you need airflow, making them perfect for temporary setups, spot cooling, or small areas. Fixed fans stay mounted in one spot and work well for permanent installations in large, busy facilities. Choosing between them depends on whether your workspace layout changes or not.

Key Factors to Consider When Selecting an Industrial Fan

Airflow Requirements

When choosing an industrial fan, you need to figure out how much air it should move to keep the space comfortable and safe.

CFM, or cubic feet per minute, measures the volume of air the fan moves every minute. To calculate what you need, measure the room’s length, width, and height to get its volume, then match that with the fan’s CFM rating.

You should also check for obstructions like machinery, walls, or racks because they can block airflow and create dead spots.

Static Pressure and Application

Static pressure comes into play when air needs to move through ducts, filters, or other resistance-heavy spaces. If you work in a building with tight ducts or many bends, you need a fan that delivers higher static pressure to push air effectively.

Open areas usually do not need much static pressure, while confined or enclosed spaces demand more force to move air against resistance.

Always match the fan type to the space and its level of restriction because choosing wrong can leave parts of your system underperforming.

Energy Efficiency

You save money and help the environment when you pick an energy-efficient fan.

This means fans that use less electricity while still moving the right amount of air keep your bills down month after month. Look for fans with features like efficient motors, smart controls, and certifications such as Energy Star, which prove they meet tough efficiency standards.

Choosing energy-efficient models makes your operation more sustainable without sacrificing performance.

Noise Levels

Noise matters a lot, especially if people work near the fan all day.

Some fans create loud, constant hums that disrupt conversations, lower focus, and make the workspace feel stressful. You can find models that balance strong performance with acceptable noise levels so workers do not feel overwhelmed.

Always check the decibel ratings and think about where the fan will run.

Durability and Build Quality

A solid industrial fan should handle tough conditions without breaking down early. This is where you need to look for fans made of strong materials like steel or aluminium with coatings that resist rust and corrosion.

If your space gets dusty, humid, or even exposed to chemicals, pick a fan built specifically for those environments.

Cheap materials or flimsy designs will not last and could fail when you need them most. A durable fan keeps running despite harsh conditions, saving you from frequent repairs or replacements.

Installation and Maintenance

No one wants a fan that is frustrating to install or impossible to maintain. You should check whether the fan offers easy mounting options, clear wiring layouts, and fits your space properly.

Fans that you can install without complicated adjustments save time and reduce downtime.

This is when maintenance plays a big role because every fan needs cleaning, lubrication, or minor fixes at some point. Models designed for easy access make that work faster and safer.

Budget Considerations

Price certainly shapes your choice, but you should think beyond just the sticker cost.

A cheap fan might seem tempting at first, but it could use more energy, break down sooner, or fail to cool your space properly, costing more over time.

On the other hand, higher-quality fans may cost more upfront, but they save money on repairs, energy, and replacements. Therefore, try to balance what you spend with what you get, looking at features, durability, and performance together.

Cerexio Stamp of Guarantee on Your Heavy-Duty Industrial Fan

Cerexio’s Predictive Maintenance Platform guarantees the reliability of your heavy-duty industrial fan, as it comes equipped with powerful predictive and prescriptive analytics technology. Instead of waiting for the fan to break down or show obvious problems, Cerexio solution actively monitors its performance in real time using sensors and smart analytics. It detects early signs of wear, unusual vibrations, overheating, or airflow issues before they turn into serious failures. This gives you time to fix small problems while avoiding unexpected downtime or costly repairs.

Make Your Industrial Fan Long-Lasting with Advanced Technologies

Long-lasting fans happen when you think ahead. Advanced technologies paired with the right expertise deliver airflow, savings, and comfort that outlast expectations. Unsure where to start? Call in a professional who can help you cut through the noise. Make every dollar count and keep your fan running strong well beyond what you imagined.

FAQ about Heavy Duty Industrial Fans

A heavy-duty fan is a powerful, durable fan designed for industrial or commercial spaces. It moves large volumes of air efficiently, improving ventilation in factories, warehouses, and workshops where standard fans cannot handle harsh conditions or high airflow demands.

A heavy-duty fan clutch handles higher torque and cooling demands compared to a regular fan clutch. It engages longer and runs stronger to cool large engines, making it ideal for trucks, industrial vehicles, and extreme operating environments requiring maximum airflow.

A heavy-duty fan typically uses between 200 and 1000 watts per hour, depending on its size, type, and speed settings. Energy-efficient models help reduce power consumption while maintaining strong airflow, making them suitable for cost-conscious industrial applications.