Stock Keeping Unit (SKU) refers to a unique number or code manufacturers use to track and organise products in their inventory. A typical SKU would usually consist of a combination of numbers and/or letters specific to a product or a product variation. They become essential for tracking and transporting goods across the supply chain. In other words, it is an essential aspect of inventory management. Without an SKU code, there is no way for the warehouse operator to monitor its status or for the customer to know where their order is. This article will explain the important aspects of SKU management in warehouse operations.

Why is SKU Management Important for Warehouse Operations?

In warehouse operations, the number of items you bring into the inventory and the number of orders a manager needs to send out can be hectic. Any failure of the part of the system to record every transaction could lead to significant errors and slow-downs in the long term. As supply chains are complex networks and fast-moving, warehouse managers have to stay on their toes to eliminate errors. Whether it is to ensure the right item is picked out and packed or note the right order is sent to the right person, the number of things that can go wrong in a supply chain is multiple. Hence, with no proper SKU management, a warehouse could succumb to losses at an increased rate.

Factors That Need to Be Considered When Generating an SKU Code

SKU specifically refers to the unique code that helps with tracking packages. This code includes abbreviated attributes of multiple features, including details relating to the colour, materials, supplier, model, packaging and related aspects of the product in question. Note there are no universal attributes that have to be mentioned. Hence, different warehouses prioritise key attributes in making SKIs according to their preference. Thus, just by seeing the code, warehouse managers that can interpret the code can easily know what the product is. But how is this code even made, and how can one guarantee it is unique? Here are a few factors warehouse managers should consider when generating SKU codes:

Dividing Products into Categories

One of the best ways to keep your inventory organised is by arranging your warehouse by specifying your SKU numbers based on the categorisation you made. Hence, track and find the exact product in the inventory by looking for the vendor, type, collection and other choices of specification the manager deems important. Since there is no limit to the number of characters that can be added to an SKU code, multiple factors can be specified within the code to identify the different categorisations the item has been allotted to. Once an SKU has been made with a specific set of characters, note that a similar format needs to remain consistent. This streamlines the process of finding and delivering your packages much faster. It is through such information managers can moreover assess whether there is an overstock for future orders. Managers can also find what collection of items or vendors are regarded as best sellers and make smart inventory decisions based on such findings.

Taking Care to Note that It Is Different From Your UPC Code

Many confuse their SKU numbers with the universal product code(UPC). The UPC is a standardised 12-digit number to identify a product similar to the SKU scanned. While the point of an SKU number is to guarantee identification, the primary difference lies in the purpose. While an SKU is a code generated by the warehouse, a UPC is the identification code set by the manufacturer. This is usually issued by the Global Standard Organisation to the manufacturer, and copies of the same product have the same UPC. An SKU number differs according to the seller, whereas a UPC number can be the same for the same product regardless of the seller. A UPC cannot be interpreted as SKU can from its code formation. A main reason for this is also because UPC only consists of numbers. This is the key reason warehouse managers implement an SKU so that their robots and staff can easily understand the products being tracked by the unique alphanumeric code.

Specify the Top-Level, Unique and Sequential Identification Codes

The typical formal SKU system requires you to add numbers and characters in a specific way. For instance, managers must have a top-level identifier at the beginning of each SKU. This can usually be two to three characters and is a general classification of the product categorisation the manager decided on earlier. It is these first characters that will help managers to locate products in the store with one glance. Next, the unique number that distinguishes every item from another is placed in the middle section of the SKU. Factors such as size, colour and other subcategorisations may be regarded as unique by the warehouse operator when setting this identifier. Lastly, every SKU must end with a sequential number. The main purpose of this is to distinguish between new stocks and old stocks. Hence, managers can prioritise their sales when managing orders by knowing which item is older or relatively new. Once made, they are added to an inventory management system, and barcodes are created.

Cerexio Smart WMS: An All-In-One Solution to Streamline Your Warehouse Operations

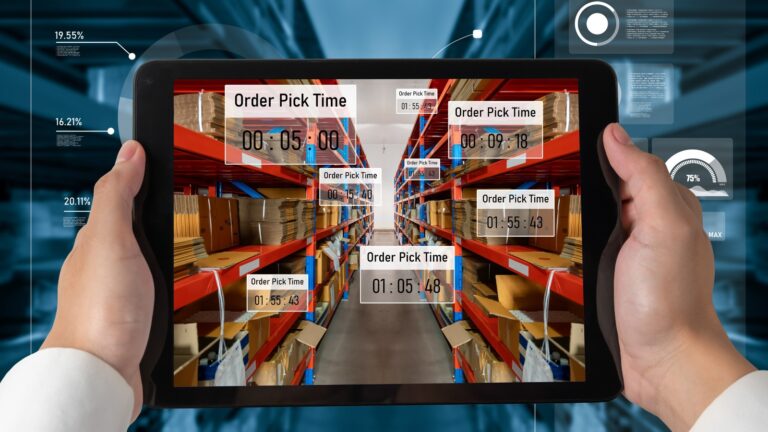

Cerexio Smart WMS is an all-in-one solution that helps warehouse managers to streamline their operations. It optimises your storage area and distribution centres through intelligence information systems, looking for the easiest and most convenient way to store, pick up and deliver packages around the warehouse. It compliments robotic forklift fleets that use advanced AI, AGVIs, AMRs and others, allowing machines to navigate within the warehouse with minimum interruption or supervision from humans. One of the most central aspects of WMS is that it takes care of inventory management. For example, it utilises the various industry 4.0 technologies embedded into its system to unlock hidden insights. Hence, the data analytical capabilities the solution is equipped with can draw out reliable insights, particularly on consumer and market trends. Based on such information, consumers can ensure enough items are stocked to ensure maximum sales are made. Receive notifications in advance where goods in the inventory are not available and restock them as soon as possible.

Cerexio also helps to make the supply chain much more transparent by informing you of where every order is a all times. With its enhanced tracking capabilities, you or the consumer can check for their order status in seconds. Keeping everyone in the loop is guaranteed to increase customer satisfaction, thus helping you increase your reputation as a trusted warehouse manager.

Connect with us to learn how else a smart warehouse solution can help you unlock your full potential.

Specify the Top-Level, Unique and Sequential Identification Codes

Having knowledge of what items have higher demand among consumers is a great way to know how much exactly you should order when restocking your inventory. Usually, managers can order way less or more than required, resulting in losses being incurred in either situation. In an asset-centric industry, the number of expenses warehouses must handle is enormous. Hence, one way to significantly reduce your finances is by having an effective system in place for SKU management. The most mindful the manager is the more profit that can be accumulated. Hence, focus on organising and streamlining your SKU management tactics.

This article is prepared by Cerexio, a leading technology vendor that offers specialised solutions in the Advanced Manufacturing Technology Sector. The company is headquartered in Singapore and has offices even in Australia. Cerexio consists of a team of experts that have years of experience and holds detailed knowledge on a range of subject matters centric to the latest technologies offered in manufacturing and warehouse operations, as well as in predictive maintenance, digital twin, PLC & instrumentation setup, enterprise integrator, data analytics and total investment system.