It goes without saying that workforce training offers impressive benefits for organisations in the manufacturing industry. It is evident that a strong training and development program can have numerous benefits. But the point is it has to be valuable yet practical. How can you strike the right balance between these two factors? That is where you need cutting-edge technology such as ‘Augmented Reality’ or, in short AR technology.

In this article, you will learn everything about the employment of AR technology, the key challenges in workforce training in the manufacturing industry, and how it provides answers to all the matters with its functionalities.

What is Augmented Reality?

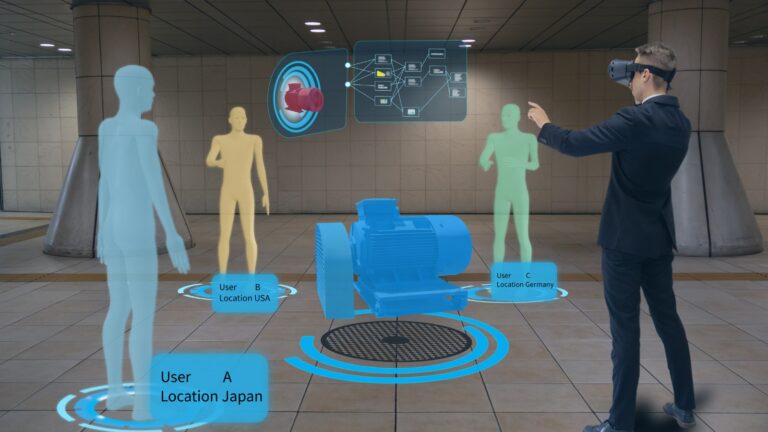

AR is a technology that blends digital information and virtual objects with the real world. It overlays computer-generated images, animations, or data onto a user’s view of their physical surroundings through a device like a smartphone, tablet, or AR headset. If further elaborated, It is an enhanced version of the real physical world that is achieved through the use of digital visual elements, sound, or other sensory stimuli and delivered via technology.

This technology offers a better way to design, curate, and deliver consumable instructions by overlaying digital content in real-world work environments. Everyone can collaborate effectively while working remotely when a company implements this technology in order to gain some enlightenment. This solution is often collaborated with VR technology which is known as Virtual Reality. No matter what the industry is, this digital capability provides the best service for employee training, skill development, and whatnot.

Major Workforce Obstacles Encountered in Manufacturing

Complexity of the Working Environment

The operating environment in the industrial sector significantly relies on complex and high-tech devices and infrastructure. Although these complex structures create a basis for manufacturing procedures, no need to say they provide significant headaches for the authorities when it comes to staff training.

What is most challenging here is ensuring all employees have the knowledge and abilities required to operate and maintain these modern devices in the first place. The skills are needed for the staff as it directly affects productivity, safety, and overall product quality.

Keeping Up-To-Date with Rapidly Evolving Technology

We have come to an age where technology is advancing at lightning speed. The manufacturing industry is currently witnessing the integration of cutting-edge Industry 4.0 capabilities such as automation, the Internet of Things (IoT), and Artificial Intelligence (AI) etc.

It is quite important for them to stay relevant to the industry standards. In one way while these innovations bring tremendous benefits, the other way they also present ongoing challenges. What are these challenges? keeping their workforce up-to-speed with these ever-evolving technologies is major. Ensuring that employees can confidently adapt to these new tools and methods is also another concern. This can vary from regular training to retraining initiatives.

Safety Concerns

One thing in the manufacturing industry that can not be compromised is safety compliance. Singapore has strict laws requiring compliance with severe rules and expertise in safety procedures. However, it is extremely difficult to ensure thorough training, constant adherence, and persistent attention among all staff.

It requires not just training workers but also developing a strong commitment to safety. This is because compliance can change over time, especially in situations of high stress. That is why the manufacturing authorities are in need of robust technology and tools to adhere to these lawful environments in Singapore.

How to Optimise Workforce Training Utilising AR Technology

Elevated Employee Safety

As we discussed above, manufacturing plants are coupled with various complicated machinery. In factories, the assets that are enriched with AR technology help keep workers safe. But how? They show important safety messages and warnings about machines and potential dangers in real-time, which makes workers stay aware and safe.

Also, AR makes safety training, like practising for emergencies, more practical and safe in a virtual world. This helps workers be ready for real-life emergencies. It is quite visible that AR lowers the chance of accidents, making employees more aware of dangers and practically demonstrating how to adhere to safety standards.

Performance Analytics

This technology expresses a powerful integration with other synchronised tools and software. When a company integrates analytics tools into AR training systems, the authorities can monitor how well employees are committing to their KPIs and how they are improving.

This data is valuable as it pinpoints where employees might need more training. Utilising this knowledge, manufacturers can focus on particular areas to assist them in becoming even better at their employment. It is a ‘road map’ that brings the businesses up to a competitive edge.

Customisable Training Modules

Not every business needs the same set of competencies from their staff. On the other hand, not every worker needs to be through with the same set of skills. This means the requirement of skills varies from company to company and person to person. The training that is focused on the employees needs to be tailored to the business requirements accordingly. This is possible with the AR solution.

The latter’s tailored training modules, which offer exact and job-specific guidance, ensure that employees receive training that is relevant to their responsibilities. This strategy enhances the value of the learning experience by making sure it is both pertinent and focused. Plus, it assists employees in gaining the information and abilities they need to succeed in their particular positions.

Realistic Simulations

Do you know that this technology can develop lifelike simulations that replicate actual manufacturing situations? The best thing about them is they enable employees to rehearse tasks, identify and address problems, and enhance their skills in a secure and controlled virtual setting. These simulations reduce the possibility of errors and accidents by offering a risk-free setting for practical training as we mentioned above.

They encourage employees to gain confidence and competence, ensuring that they are well-equipped to deal with issues that arise during production. This is the best way to create a workplace that is safer and more productive. Employees also have the ability to sharpen their skills without running the danger of doing so in the actual world.

On-Point Feedback and Evaluation

Another benefit of the latter is it extends the hand for authorities to consistently assess the AR training program’s impact at the end of each session. It is done by gathering employee feedback and analysing performance data both in the short term and long term. This ongoing evaluation process allows manufacturers to stress the areas that need improvement and make necessary adjustments.

The authorities can guarantee that the AR training constantly adapts to fit their needs by including employee feedback and performance indicators. This creates a more efficient and interesting learning environment as the outcome.

Cerexio Empowered AR Technology

Cerexio provides the best way to manage workforce training through AR solutions that are coupled with ‘Virtual Reality’ or VR technology. While AR overlays virtual features over the real world to perform user-defined activities, VR offers immersive simulated experiences for users to achieve goals. With the employment of cutting-edge Cerexio AR & VR solutions, you can gain actionable data from various sources and conduct immersive professional training to identify abnormal data patterns and suboptimal machine functionalities, etc.

Levelling Up Your Business with Robust Technology

Why do you need to rely on manual and traditional methods to upgrade your business when you have convenient and advanced tools to help with? Technology is something that you should be applying to the right places with the right strategies. With modern-day software solutions, what you desire is not that difficult to touch.