Are you feeling your manufacturing process is overwhelmed by unlimited responsibilities? Then, the Digital Factory is your final destination. Industry 4.0 has become a revolutionary force in the rapidly evolving industrial world, transforming how businesses operate and develop. The digital factory is at the centre of Industry 4.0, which is primarily the union of cutting-edge technology with conventional production.

In our latest blog article, we embark on a journey to explore the profound impact of this digital revolution while exploring its characteristics and the benefits it can provide you with.

What is a 'Digital Factory'?

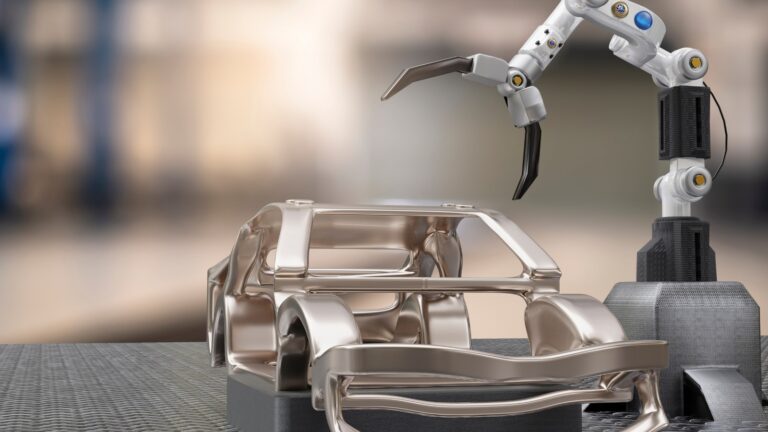

This is one of the revolutionary technologies that aided in reshaping the world of manufacturing within a short time. It refers to the integration of advanced digital tools and technologies within manufacturing processes to optimise efficiency, quality, and productivity inside the factories. This is not a technology that stands alone, but it is a pinnacle of various robust technologies, including the Industrial Internet of Things (IIoT), artificial intelligence (AI), data analytics, automation, etc. If further explained, when it comes to Digital Factory, machines communicate and cooperate. This helps in generating vast amounts of data that can be analysed in real-time to make data-driven decisions and improve operations.

This cutting-edge technology is enriched with predictive maintenance capabilities that aid in, reducing downtime and costs. In the manufacturing arena, Digital Factory technology is known as a potent tool that heavily enhances product customisation and response capacity to ever-changing market demands. Digital Factory technology is revolutionising traditional manufacturing procedures, making a smart movement toward the rising industrial demands and expectations through the powers of Industry 4.0.

This is What Distinguishes the Digital Factory

Robust Integration with Other Software

As we mentioned earlier, this tool can serve a wide range when it is integrated with other software. Its ability to integrate with other software systems stands out as a revolutionary characteristic of this technology. If we emphasise the perks, this integration capability allows seamless coordination and data exchange between various software applications and components within the manufacturing realm. As we discussed, Digital Factories rely on various capabilities of interconnected systems, including CAD/CAM software, Enterprise Resource Planning (ERP) systems, production management software, and even customer relationship management (CRM) tools.

This blend of straightforward tools inspired by Industry 4.0 ensures that manufacturing data flows effortlessly, enhancing efficiency and providing real-time insights. Digital Factory not only streamlines operations but also speeds up responses to changing market conditions. As one of the key components of the Digital Factory, the integration of necessary software enables companies to increase productivity and competitiveness without wasting time and money.

A Connected Ecosystem

In the above section, we looked into this technology for its powerful integration with other industry 4.0 software. As an outcome, its robust synchronisation with machines, sensors, software systems, and workers makes this technology a comprehensive network. It is evident that everything is interconnected when it comes to the Digital Factory. This uniqueness is what encourages the system to foster real-time communication and data exchange.

If we look into this further, machines connected through the digital category can communicate with each other, and sensors provide continuous data streams while the workers access information through digital interfaces. This is exactly what allows manufacturers to monitor and manage operations remotely and improve efficiency. This aids in making data-driven industrial decisions at the end. There is no need to mention that this connects the various parties in the manufacturing process, varying from stakeholders, employees, suppliers, etc. With Digital Factory in their hands, manufacturers can look into various aspects through one singular platform, and the whole process is in their hands.

This is Why Manufacturers Need Digital Factory

Optimising Operational Efficiency

Let us walk you through how Digital Factory technology revolutionises manufacturing by optimising operational efficiency. This occurs in multiple ways. First, Real-time data analytics and sensor integration enable precise monitoring and control of production processes. This effort leads to reducing waste and streamlining their operations. Again, Automation and robotics enhance productivity, minimising labour costs and errors while ensuring consistency.

On the other hand, as we mentioned above, Predictive maintenance prevents equipment downtime by proactively addressing issues in the first place. This indeed helps with uninterrupted production in the manufacturing business. Then again, as the digital tools powered by Industry 4.0 aid in demand forecasting and inventory management, it optimises supply chain operations for faster response to market changes and reduced carrying costs.

Adhering to Sustainability and Accomplishing Business Goals

Manufacturing is a place that puts a lot of attention to sustainability efforts. Do you know why? That is because due to their production, there is a high possibility of harming the environment more than other industries. This is why sustainability has been introduced by the Singaporean government as a value to the manufacturing industry.

It is visible that Digital Factory technology encourages optimising resource utilisation through real-time monitoring and data-driven insights. What would be the outcome of implementing this tool? Yes, as a result, it reduces energy consumption, minimises waste, and lowers carbon footprints. Predictive maintenance and improved automation not only increase productivity but also extend the life of equipment, preventing costly replacements. Similarly, it gives manufacturers the ability to react quickly to changes in market demand, reducing overproduction and excess stock, which can result in wasteful spending and the environment.

Providing Customised Answers to Market Demands

It is common knowledge that the manufacturing industry is subjected to regular changes. Sometimes, you can not rely on the planned strategies and adhere to the same procedures again and again. It requires the involvement of creative and customised solutions. Digital Factory technology empowers manufacturing by tailoring responses to market demands in real time.

If further explained, due to the powers of real-time data analytics, production processes can be swiftly adjusted to align with shifting customer preferences and market trends. We should not forget that robotics and automation provide flexible manufacturing, allowing for the quick and efficient creation of customised items. This is not as difficult as it seems to be. As the system is integrating supply chain data and demand forecasting, manufacturers can now assume market needs and fine-tune production schedules accordingly. This majorly assists them in reducing excess inventory and minimising waste during the production process.

Enabling Flexibility in Production

Flexibility is another element that manufacturers expect from the technological solutions they couple with. When they receive backup from this robust technology and the industry 4.0 powers, manufacturers can seamlessly reconfigure production lines and processes to accommodate variations in product specifications or shifts in demand. That is also without extended downtime.

Do you know that industry 4.0 powered Digital Factory couples with collaborative robots (cobots)? This synergy plays a pivotal role in enabling agile, on-the-fly adjustments, while predictive maintenance ensures equipment reliability even during these transitions. This adaptability improves resource allocation, which cuts waste and costs while also improving responsiveness to client demands.

Cerexio Digital Factory

Cerexio Digital Factory is powered by industry 4.0 technologies and has gained popularity as the ideal solution for manufacturing facilities that have started moving forward in their smart journey. Cerexio is known for its ability to assist large industrial organisations in changing their corporate cultures into a powerful digitised network. Our manufacturing software packages are carefully created to assist your factories in fitting the characteristics of cutting-edge digital factories.

Shine to the Best with New Technology

Since you have read our blog article you are surely empowered to make a smart movement towards the digitised production world. If you have suitable tools with you, it will be a convenient path you will be walking on. The technology not only helps you with accomplishing your goals but also it will stand out from the competition for sure.