Preventive to predictive, why matters?

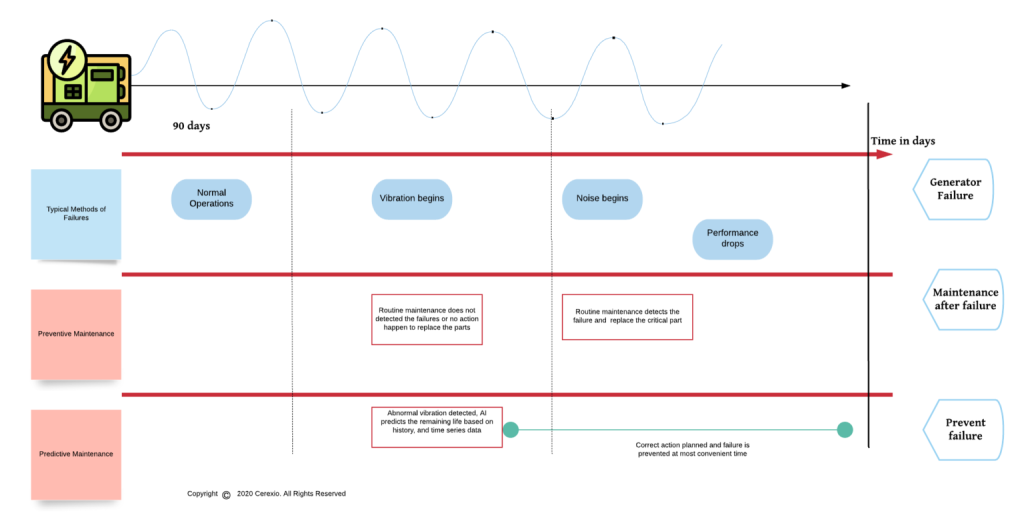

Accurately predict when equipment is likely to fail not only enables reduced downtime, it makes maintainers and asset managers optimize maintenance activities.

- Reduce downtime

- Increase productivity and operational effectiveness

- Improve safety and security mechanisms

- A better understanding of the root causes of failures

- Derive asset values, even for the machinery of varying age and conditions

- Plan and execute advanced supply chain methods

Predictive maintenance is fundamentally driven by sensors continually capturing data from equipment in the field, optionally processing it at the edge before transmitting critical data to a centrally hosted system for both near real-time and historical analysis.

Already pre-trained machine learning models are capable of detecting anomalies, suspicious behaviours and predict equipment failures, performance degradation, and process distribution.

At Cerexio, we are leveraging industrial AI technologies to accurately monitor the current condition of machines or any type of industrial equipment, using automated low-latency real-time analytics and pre-trained machine learning models. By employing real-time predictive analytics on an array of industrial IIoT data, process manufacturers have clear visibility into production processes and their losses compared to time-based preventive mechanisms.