Manufacturing is a domain where we witness the expansion and invention of new trends every year. The complexity of the manufacturing industry requires some cutting-edge solutions where they can simplify their workload from production and warehousing to distribution. ‘Industrial Automation’ is a concept and technology that has been developed to offer a helping hand to the manufacturing ecosystem. They keep changing their shape according to the evolving requirements of the sector.

In this article, we are going to reveal everything about industrial automation and its trends in Singapore for 2024.

What is Industrial Automation?

Before going further, we should understand the true essence of the idea behind this. Industrial automation refers to the use of technology and control systems to streamline and optimise manufacturing processes. This is mostly used to reduce the need for human intervention by thinking about labour shortages and possible human errors.

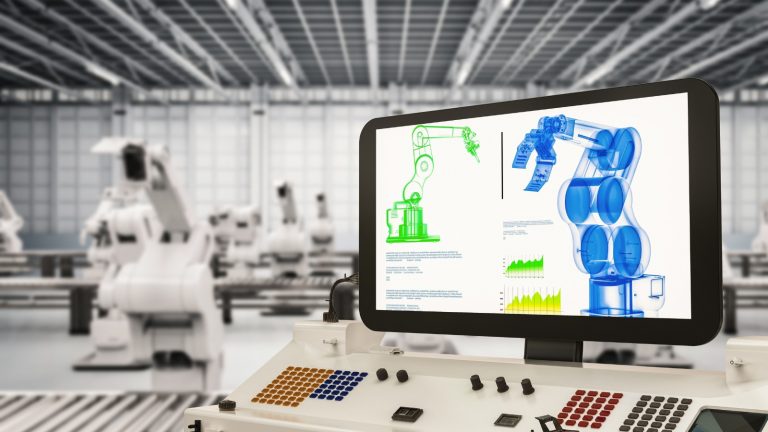

Now let us explain how this occurs in the manufacturing world. It involves the integration of various hardware and software components, such as sensors, actuators, robots, and computer systems. These devices and machines are used to monitor and control industrial machinery and processes.

Why is the manufacturing world interested in automation in the first place? Well, the answer is so obvious! Waste and errors are the number one enemy in this sector. Their main objective is to get the maximum yield out of every bit of extruder, material, machine, and process.

However, with manual processing, this cannot be 100% achieved. On the other hand, industrial automation aims to improve efficiency, accuracy, and productivity while minimising errors, waste, and downtime.

From automating repetitive tasks and utilising advanced technologies such as artificial intelligence and machine learning to promising perfection in every process, industrial automation is the way to establish faster production cycles, higher-quality products, and better resource utilisation.

The time has come for the Singaporean manufacturing domain to start walking towards industrial excellence with new technology. In this sense, industrial automation transforms traditional manufacturing operations into smart, interconnected systems. They have the optimal capacity to adapt to changing demands and drive innovation in various industries, which is an absolute advantage.

Top 5 Industrial Automation Trends in Singapore for 2024

Integrating AI with Industrial Automation

Not just in the manufacturing world, but all around the world, this has been the ‘talk of the town’ for some time now. Why are they planning to add AI as a potent part of industrial automation? The answer is not that complicated, for sure.

AI brings the capability to analyse vast amounts of data in real time in the first place. It is visible that it allows for predictive maintenance, process optimisation, and enhanced decision-making inside the automation cycle without making errors.

Through the use of AI algorithms, industrial automation systems can identify patterns, anomalies, and potential issues before they occur, which is quite beneficial in unforeseen scenarios. With this capacity in hand, manufacturers can reduce downtime and increase operational efficiency within their process framework.

In one way, AI offers adaptive and self-learning systems that can continuously improve performance over time. This integration also helps with greater flexibility and agility in manufacturing, backing up rapid adaptation to changing market demands and production requirements.

As you can see, the synergy between AI and industrial automation promises to unlock new levels of productivity, quality, and innovation in the manufacturing industry in Singapore.

Additive Manufacturing (3D Printing)

This encourages the on-demand production of complex parts with minimal waste, reducing inventory costs and lead times.

Integrating 3D printing into automation workflows allows for rapid prototyping, customisation, and iteration of components, speeding up product development cycles.

Furthermore, automation can enhance the efficiency of 3D printing processes by automating tasks such as part orientation, support generation, and post-processing, reducing labour requirements and increasing throughput.

Plus, automation can facilitate the integration of 3D printing with other manufacturing processes, such as CNC machining and injection moulding, to create hybrid manufacturing systems capable of producing a wider range of parts with increased efficiency and flexibility.

It is evident that when the manufacturing processes are coupled with additive manufacturing or 3D printing, it offers faster, more cost-effective, and customisable production methods, which is highly advantageous in enhancing client satisfaction.

Collaborative Robots (Cobots)

The employment of various types of robotics on the manufacturing floors is not a new thing for Singapore. However, utilising them in the regular factory tasks targeting the perfection of production lines and the workflow is definitely in the scenario of industrial automation.

They are so popular due to their ability to revolutionise the way humans and machines work together on the factory floor. Unlike traditional industrial robots, Cobots are designed to operate safely alongside human workers, facilitating a more flexible and adaptive manufacturing environment.

This collaboration optimises automation by improving efficiency, productivity, and worker safety. Cobots can do laborious or exhausting jobs, freeing up human workers to concentrate on deeper and more intellectual activities that require human creative thinking and problem-solving abilities.

Furthermore, cobots are easily reprogrammable for a variety of jobs, allowing for quick transitions and flexible manufacturing procedures. You know that their compact size and lightweight design make them suitable for use in small and medium-sized enterprises because, in such organisations, the space and resources are limited.

Edge Computing in Industrial Automation

Because it can solve many of the major issues with traditional centralised computer systems, edge computing is set to become a major trend in industrial automation.

Edge computing lowers latency and bandwidth consumption by processing data closer to the source, at the network’s edge, facilitating real-time analysis and decision-making.

This is especially important for industrial automation since operating efficiency and safety can be affected by milliseconds.

Edge computing also enhances data security by minimising the need to transmit sensitive information over long distances. Also, it relieves the strain on centralised systems, enhancing scalability and dependability by dividing computational tasks across edge devices.

Predictive Maintenance

Maintenance is an essential part of any manufacturing ecosystem. What if it can predict potential maintenance scenarios? Yes, that is exactly what predictive maintenance is all about!

This has become a significant trend in industrial automation due to its ability to optimise automation processes and enhance efficiency.

This is made possible via the use of data analytics, sensor technologies, and machine learning algorithms that are embedded in the assets. Predictive maintenance allows for the early detection of equipment failures and performance degradation, allowing proactive maintenance interventions before issues escalate.

This approach minimises unplanned downtime, which is its best benefit. Also, it reduces maintenance costs and extends the lifespan of machinery and assets. Integrating predictive maintenance into automation systems also helps with better resource allocation, as maintenance activities can be scheduled based on actual equipment conditions rather than predefined time intervals.

Predictive maintenance also makes predictive analytics-driven decision-making easier, which helps organisations manage spare parts stocks more effectively, optimise production schedules, and raise the overall reliability of their equipment.

With the synergy of predictive maintenance and predictive analytics, industrial automation promises to enhance operational resilience by up to 200%.

Cerexio for Cutting-Edge Industrial Automation

Cerexio solutions are highly adaptable to any evolving trend in the manufacturing world, as our software is powered by Industry 4.0 digital capabilities. From enhancing efficiency, boosting productivity, and cost-savings to ultimately expecting maximum ROI, Cerexio leads the way for your manufacturing realm to find production and distribution perfection.

Optimising Industrial Automation for Better Results

Since industrial automation has become a new trend, manufacturers who seek innovative ways to revolutionise their workflows should try it out in a strategic way. If you are not confident enough to make this brave movement yet, there are many consultation services available in Singapore to help you with that.