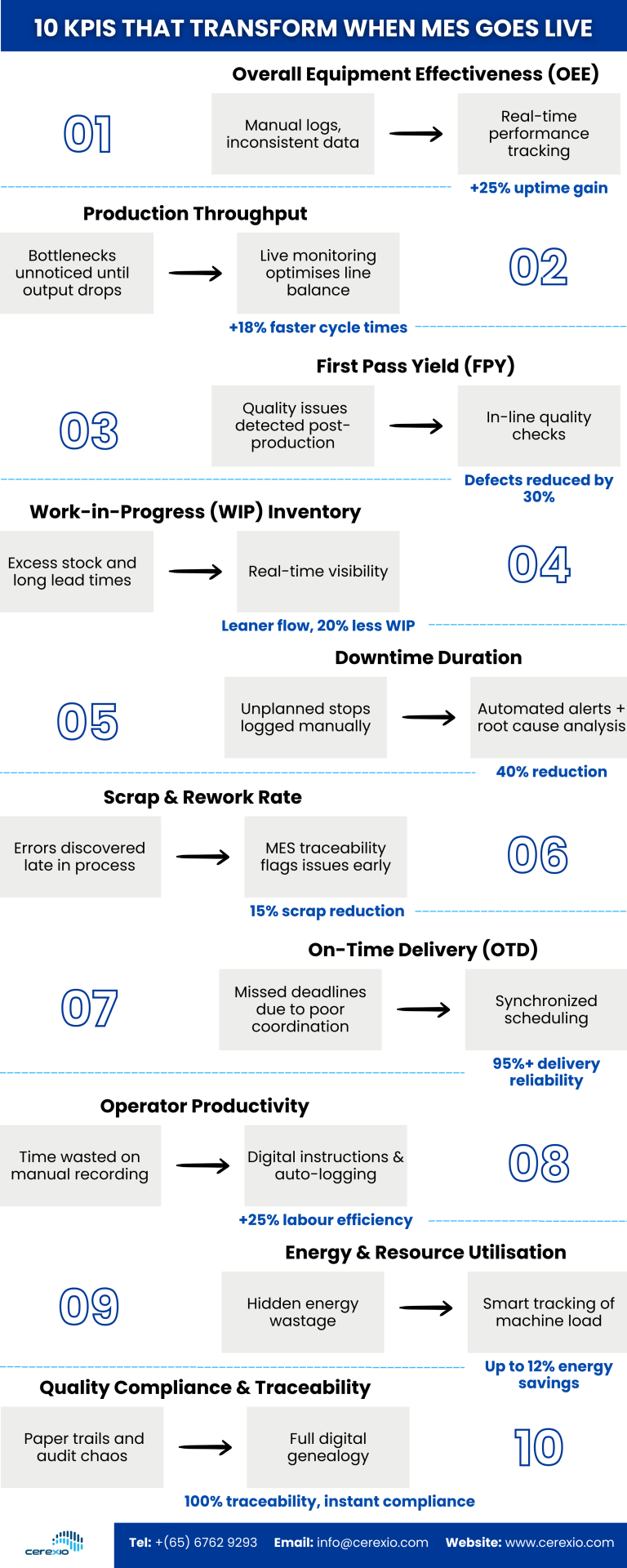

When a Manufacturing Execution System (MES) goes live, its impact is felt most clearly through the KPIs that define daily manufacturing performance. Metrics that were once difficult to track, delayed, or dependent on manual data collection become transparent, real-time, and actionable. Core indicators such as Overall Equipment Effectiveness (OEE) shift from inconsistent manual logs to live performance tracking, unlocking higher uptime and faster response to issues. Production throughput improves as bottlenecks are identified instantly, while first pass yield benefits from in-line quality checks rather than post-production inspection. Visibility into work-in-progress inventory enables leaner flows and shorter lead times, and downtime duration drops significantly through automated alerts and root cause analysis.

MES also plays a critical role in reducing scrap and rework by flagging deviations early, improving on-time delivery through synchronized scheduling, and boosting operator productivity with digital work instructions and auto-logging. Beyond operational efficiency, energy and resource utilization become measurable, revealing hidden waste, while quality compliance and traceability move from paper-based chaos to full digital genealogy. Together, these KPI improvements translate into better decision-making, stronger customer confidence, and a more resilient manufacturing operation. To clearly illustrate how each KPI transforms before and after MES go-live, we’ve captured the full picture in the infographic below.