The chemical manufacturing industry is a landscape where we see severely complex operational processes and outcomes. According to research, the changing demand for the chemical industry is mostly due to its usage as a raw material in industrial sectors such as paper and pulp, food and beverage, textiles, polymers, agriculture, and more. As the demand for these industries goes up, the demand for chemicals also rises. However, the huge demand for chemicals leads to some interwoven challenges in business operations. That is where the chemical manufacturers started seeking innovative solutions and landed with something known as ‘Industrial Internet-of-Things’ or, in short, IIoT technology.

In this article, we explore how 5G IIoT technology provides answers to the challenges faced by the chemical industry when serving that rapid demand.

Exploring IIoT Systems

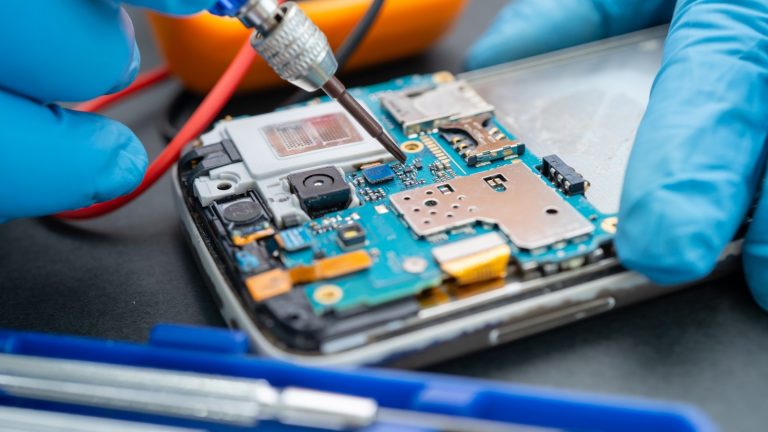

With the help of solid digital connections such as 5G, this revolutionary change in technology expands industrial processes. It involves the integration of sensors, devices, and machinery with the internet to collect and share data in real-time, fostering enhanced automation and informed decision-making. Apart from that, 5G IIoT technology empowers various industries with its ability for predictive maintenance, remote monitoring, and data-driven insights.

In addition to improving operational efficiency, the industry 4.0-powered industrial Internet of Things clears the road for stakeholders to cost savings via the seamless interchange of information across the infrastructure, logistics, and manufacturing sectors. This innovative technology transforms the way industries work and paves the way for more connected, intelligent, and flexible industrial ecosystems, bringing all the aspects under one singular platform.

Problems Faced by Chemical Manufacturers

Lack of Visibility

The complexity of chemical supply chains can lead to limited visibility, making it challenging for suppliers to track inventory and product usage. As far as the chemical industry is concerned, accurate inventory and supply chain management are quite important aspects of cost reduction and maintaining product quality. The visibility is necessary to look into cost-saving opportunities while preserving quality standards within the operational background.

Managing Raw Materials

It is difficult to predict costs and maintain competitiveness in the chemical manufacturing sector because the industry relies on changeable raw material prices, such as crude oil. It is pretty important to maintain the right balance in the supply of materials since storing too much can lead to waste, and too little might make it difficult to meet client demands.

Controlling Environmental Impact

The environment is one of the major concerns when the chemical industry is concerned, and understanding the importance of keeping operations away from harming the earth, the Singaporean government has put much pressure on this aspect. However, it is not that easy to control its environmental impact. Strict environmental regulations are necessary for these production procedures, waste disposal, and emissions management. Adhering to regulatory compliance is an ongoing struggle for this particular industry. The responsibility does not end here. While reducing the environmental impact of the chemicals they produce, the industry requires a careful balance between economic viability and environmental responsibility.

Complex Supply Chains

The chemical industry is not limited to one framework. Actually, it is known as multifaceted as it is built on diverse processes and product types, from raw materials to finished goods. Then again, it involves numerous stakeholders, from manufacturers to distributors. As there is not much room for product changes, the precision of the production line is essential. This is one way that the chemical business is different and more complicated than other industries.

Handling Large Amounts of Data

The chemical manufacturing industry seems to be struggling with the challenge of managing the vast volumes of data it gathers. Data gathering and analysis are regularly done when it comes to everything from manufacturing procedures to safety regulations. This is the reason for ensuring the privacy and integrity of data while utilising its insights for process improvement. The issue lies in keeping up with this flood of data effectively while protecting it.

How the IIoT System Benefits the Chemical Manufacturing Industry

Allowing Modular Automation

The IIoT is capable of allowing manufacturing plants to adapt to market demands without limitations through the employment of technological solutions. Through interconnected systems and real-time data exchange, chemical production processes become stronger and more responsive. Manufacturers can efficiently grow their operations, making adjustments as required. That is also while maintaining high standards of safety and product quality, which is quite impressive.

This is exactly how 5G IIoT technology’s capacity for modular automation empowers the chemical sector to boost flexibility and efficiency as the outcome. The application of the latter helps it stay on top of the competition and meet the dynamic needs of the market.

Accessing Real-Time Data and Providing Visibility

Another way the IIoT platform is revolutionising the chemical manufacturing industry is by granting access to real-time data. The tool offers unparalleled visibility across the entire manufacturing process, from raw feedstock to the end product. When monitoring and analysing crucial factors, manufacturers can ensure effective production overall. Plus, it helps maintain product quality and react quickly to deviations or problems.

If put in simple terms, this outstanding transparency and instant access to data drive informed decision-making, improve resource allocation, and minimise downtime. When the stakeholders are equipped with those real-time insights, chemical businesses can improve their operations while eliminating waste. On the other hand, it improves workplace safety, which indirectly drives it to strengthen its competitive advantage in the market.

Digitising Equipment Health Analysis

Digitising equipment investigations is another perk of utilising IIoT in the realm of chemical manufacturing. This is a unique approach that clearly speeds up those inspections. On one hand, it can offer an extensive evaluation by comparing them to previous inspections done. On the other hand, it provides a full picture of the health of the equipment for certain asset categories. This capability makes predictive maintenance easier, identifying possible problems before they affect operations.

Talking about the benefits of this digitisation, we cannot forget that it reduces downtime, lowers maintenance costs, and enhances safety. When chemical manufacturers employ IoT devices for equipment health monitoring, the chemical industry can proactively manage its assets, staying away from unwanted failures.

Maintaining Electronic Batch Manufacturing Records

The IIoT gateway is at the top of the lists that back up initiatives to maintain some electronic batch manufacturing records. As it is enriched with Industry 4.0 capabilities, it empowers chemical companies to maintain comprehensive digital records with powerful data integrity. This helps reduce the headache of regulatory reporting. Since the latter expresses its potency to seamlessly integrate and utilise this data for regulatory purposes, it acts as a technological companion to the reporting process. Plus, this assists in eliminating administrative burdens and minimising the risk of errors.

As we mentioned before, this powerful synergy of tools not only enhances transparency but also boosts efficiency. Ultimately, it allows chemical manufacturers to meet the strict regulatory standards the government has posed while promoting operational excellence as well.

Optimising Sustainability Initiatives

As we mentioned previously, the environment is the number one factor that comes to mind when talking about this specific industry. As it makes it possible to receive real-time data and insights into resource consumption, emissions, and waste management, the IIoT system’s application helps with sustainability efforts. How can it be done? This is not that difficult, as it extends a helping hand for the manufacturers to monitor and reduce their environmental footprint. This data-driven approach not only enhances eco-efficiency but also supports compliance with strict environmental regulations.

If explained more, IIoT is powered by predictive maintenance modules, which help the industry reduce equipment-related waste and energy consumption. With this technology in use, manufacturers can save their reputation in a world where the environment receives so much attention.

Cerexio Empowered IIoT Technology

Cerexio offers cutting-edge technological solutions, driven by IIoT automation, that facilitate seamless connectivity for industrial professionals across complex industrial networks. These solutions boost machine-to-machine synchronisation and empower plant managers with actionable data. Cerexio combines IIoT and IoT technologies into a unified suite for comprehensive industrial insights and management. If you are seeking innovative ways to shoot the arrow towards business success, The Cerexio IIoT gateway is something you should try.

Walking Towards Chemical Industry’s Glory with Technology

The sole purpose of bringing this article to you is to emphasise the importance of technological application where it is necessary. When the whole business landscape of the chemical industry evolves, why would you remain in the same position? Think for a moment!