Order picking, as suggested by the term, refers to the process of readying an item for package and delivery. Hence, when a customer typically places an order, the warehouse system should be able to pick it up and put it up for delivery automatically. A familiar problem warehouse managers face is ensuring the correct order is sent to the right person and optimising the order pick-up process. Order pick-ups spend an enormous time ‘dead time walking’, thereby a lot of time trying to find the right warehouse resources, especially in large warehouses. In fact, according to an article by Veeqo, 60 per cent of productive hours just walk around the warehouse between picks. One way that has been recognised to help order picking is the implementation of a Warehouse Management System (WMS) into warehouse operations. This article was elaborate on how a WMS can fix order picking problems.

What is a WMS?

Simply put, a WMS is a software solution that helps managers overlook and ensure daily warehouse operations are carried out as efficiently as possible. From picking orders, sending them for packaging, organising warehouse space, managing inventory, and others, a WMS is a multi-faceted solution to help a warehouse utilise its time productively. It helps reduce the overall cost, resources and waste generated, thereby being a massive asset for warehouse managers. The principal beneficiaries of implementing a WMS, however, are the consumers. By streamlining the mundane procedures in the warehouse, the WMS helps consumers receive their packages on time without any defects. In other words, a WMS plays an integral role in boosting a company’s reputation, gaining a database of loyal customers and ultimately striving to become an industry leader.

Five Ways WMS Solves Order Picking Problems

Order picking is not a simple process. Depending on the quality, quantity, type of material the product is made and its size, the method used for picking differs. There are currently seven recognised forms of picking: batch, zone, single order, discrete, wave, multi-order/multi-batch and cluster picking. Here are five ways a WMS platform can ensure all types of picking can execute their functions efficiently:

Reducing the Time Taken to Locate Items

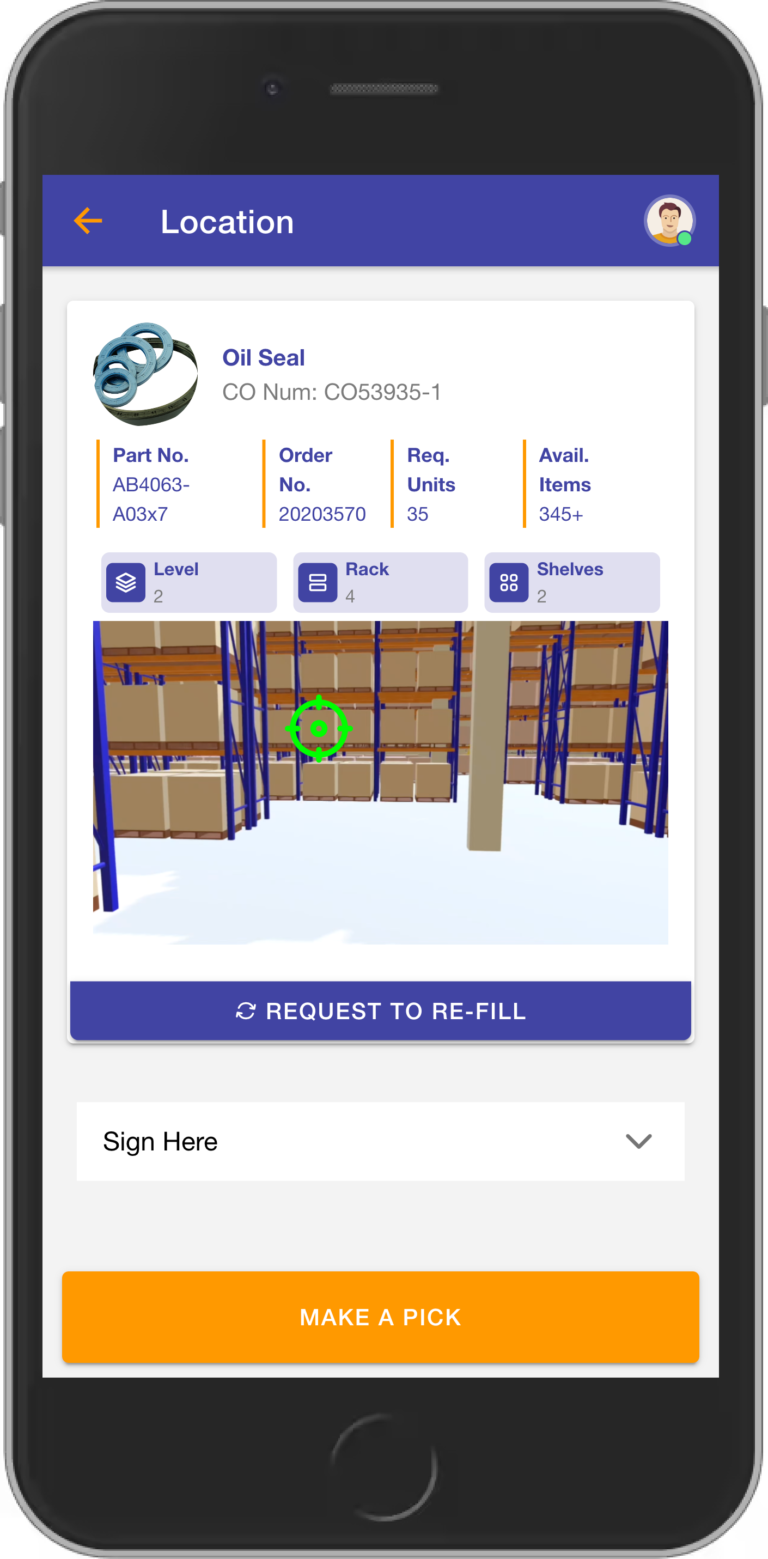

When items are not in the right place, it delays the time taken to make them ready. Consequently, a consumer’s order gets late, and companies may face the brunt of angry customers. Implementing a WMS helps to save and utilise time more efficiently. This is done by scanning each item and providing information on where it is stored in the warehouse. If it is a traditional warehouse system where a human acts as the picker, they can simply check the exact location through their mobile phone and go to the correct aisle or shelf.

Eliminating Redundancy

In big warehouse systems, it is possible for multiple pickers to pack the same order on the presumption that no one else had already sent it for delivery. One of the best ways to eliminate redundancy is by integrating robotic technology into warehouse operations. Since robots do not get tired like humans, their speed, accuracy and reliability are much greater. Hence, if an order is picked up and already sent for delivery, incorporating a WMS helps to automate the process of updating the order status. Therefore a WMS can fully eliminate repetitions.

Incomplete Orders

While a picker can choose the correct item, they may not pass on the right quantity that has been ordered. Hence, the company will still deliver an incomplete order if, for instance, only one item is sent when the order requests three. Ideally, this could be detected by those who pack the order, but where humans are susceptible to errors, this may not occur. The bar scanner can therefore be utilised for this purpose. Once an item is scanned to process an order, if the quantity of items is incorrect, it will be alerted to the picker.

Unorganised Warehouse Space

It is often found that warehouses do not fully use their enormous space. A lot of space is generally left in the middle for picking whilst all items are stored in a specific corner. A good WMS solution will allow managers to integrate a feasible warehouse map. This is a great advantage if the warehouse integrates robots to do the picking. Robots can easily be directed by a detailed floor plan to move about the warehouse without the interference of humans and accurately take down orders. Alternatively, humans who are pickers can simply implement voice picking or voice-directed warehousing that will give directions via their headphones specifying where the item is.

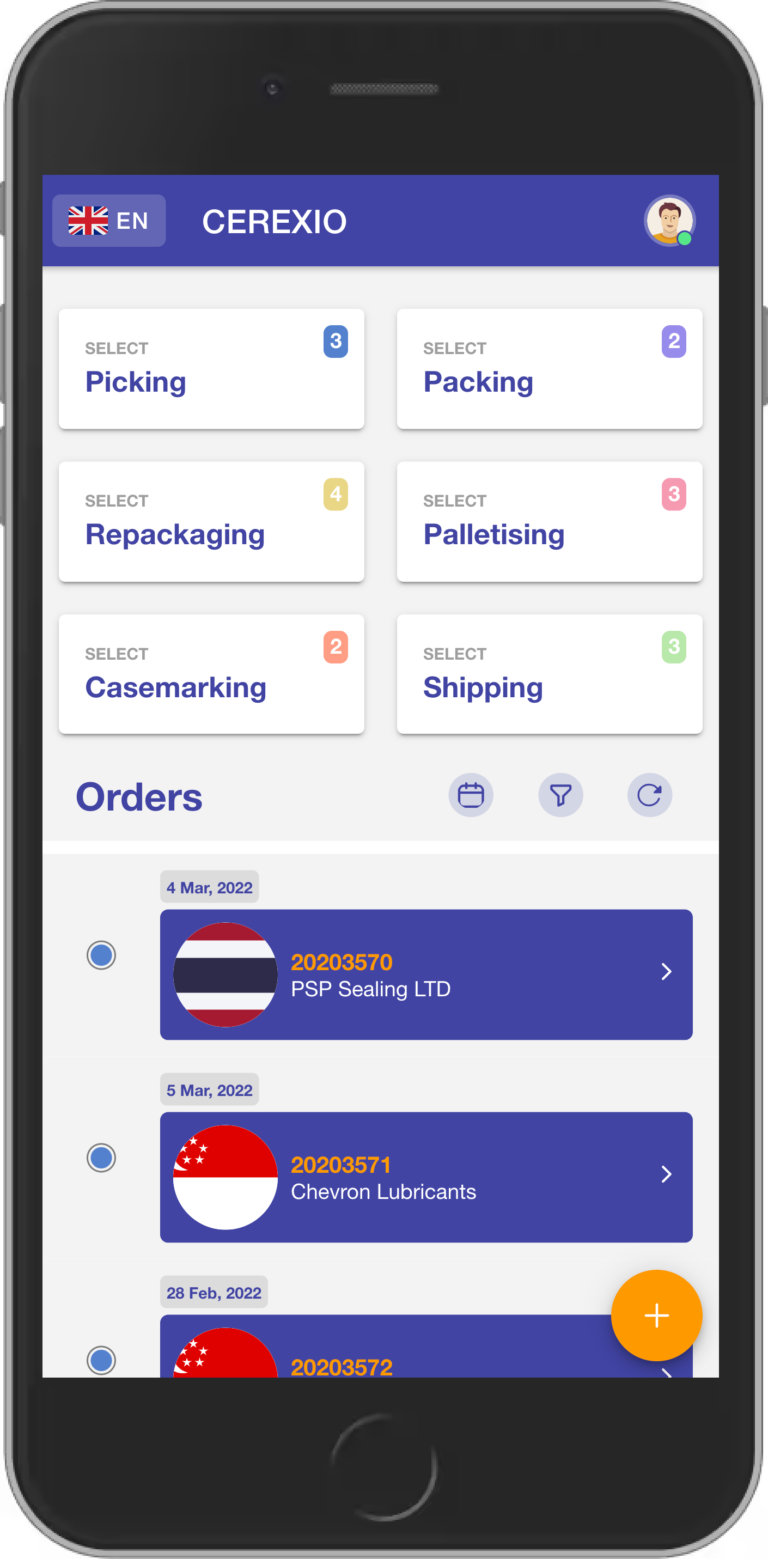

Cerexio Smart WMS: Optimising Order Picking Problems

Automate your warehouse and accurately carry out order pickings with Cerexio Smart WMS. Integrating your ASRS Systems with our advanced software solution, Cerexio Smart WMS, takes your warehouse operations to the next level. It is a compatible software deployed on any platform, such as on-prem, cloud-based or web-based. It includes a robotic forklift fleet that unlocks the power of advanced AI, AGVs, RGVs, IGVs, AMRs, UAVs, RFIDs, NFCs, cameras and sensors to navigate your warehouse operations. The solution infuses various industry 4.0 technologies, including Industrial Internet of Things (IIoT) and Predictive technologies that offer further benefits. The intelligent layout design tool helps direct robots used in warehouses to utilise the factory space efficiently. It moreover smartly directs the robots to pick up orders and accurately keep them ready for delivery. It also communicates with suppliers and delivery personnel to ensure orders are shipped on time. It helps managers cut down the overall time and resources by guaranteeing that orders are not repeated, or the wrong item is not collected by incorporating mobile barcode scanners. The cloud-based analytical tools help managers to gain valuable insights to further take action in streamlining their operations.

Connect with us to learn more about how Cerexio can help you streamline your end-to-end warehouse operations.

A WMS Is Your One-Stop Solution to Fix Your Picking Problems

Picking orders is an integral part of warehouse operations. While a traditional WMS simply helps automate a range of processes, an innovative WMS solution integrates a range of industry 4.0 technology to provide you more advantages beyond just picking an order. This means that merely implementing a WMS will not solve all your problems. Introducing robotic fleets has been a modern trend to keep up with the rising demands of consumers who expect their orders to arrive on time. Contacting a vendor that is thus able to cater for the needs of your warehouse operations without having to make drastic changes to your existing systems is vital. A vendor like Cerexio, a leading digital solutions provider in Asia and the world, is a reliable brand that can be trusted with your warehouse operations.