The manufacturing world is recently disrupted by many technologies and newer inventions like advanced composite materials, energetic materials, anti-biofouling coatings, magnets, superconductors, anti-hazard gadgets and more. With the manufacturing domain augmenting with time, the need for closely-connected fleets of smart machines has never been so important. From a technological perspective, manufacturers are now highly dependent on IIoT-driven smart machines- for a plethora of very good reasons. Today we will be educating the reader on how beneficial it is for a manufacturing centre to adopt a full-phased IIoT smart machine fleet and why.

What Exactly is IIoT-driven Smart Machine Integration

As manufacturers of the next generation are highly-dependent on data, they employ 100s to 1000s of smart machinery to automate their manufacturing operations. The concept of a ‘smart factory’ is revived with machine-to-machine integration of smart machines spurred by the power of IIoT. This technological disruption has led manufacturers to witness newly-found standards of predictability of operational events, flexibility and agility in production, plus means to cut down the negligible wastage of organisational time, money and effort.

Benefits of IIoT-powered Smart Machines for Today’s Manufacturer

Interconnectivity of Machines with Unequal Intelligent Functionalities Levels

- Machine-to-objects communication,

- Machine-to-people communication,

- People-to-machine communication, and

- People-to-objects communication.

FUN FACT: Shockingly, even in the world’s largest manufacturing country -China- with 76% of their enterprises in the electronic and electrical appliances sector use sensors to collect data, but only 33% of them use big data technology to analyse the data gathered. Yet the rate of interconnection grows rapidly with time.

Complete Autonomous Operations (As A Part of An Even Larger System)

IIoT-driven smart machines fleets led to an abrupt increase in automation levels in the manufacturing world. The importance is that this automation happens as an integral part of an even broader interconnect system; in other words, IIoT allows the manufacturing systems to be autonomous in a scalable manner. The data extracted by IIoT-powered smart machines can be fed into optimally trained AI algorithms to:

- Automate enhanced multi-connectivity of new devices,

- Interconnect Autonomous Guided Vehicles, Unmanned Aerial Vehicle, Forklifts etc.,

- Automate iterative decision-making,

- Automatically digitise manufacturing environment via simulation,

- Enable wireless data entry,

- Enable SDA (Software Defined Automation),

- Power up mechanical components to ensure embedded safety of the smart machines automatically and more.

Leverage Data for Better Manufacturing Insights

For example, when the AI and ML schemas of the mechanisms behind the analytics technology tools are trained under realistic technologies, they can use the data of the smart machines to understand the OEE levels, performance integrity and efficiency of in-house machines compared to the near-real-time market demands. This decreases the memory costs astoundingly and allows unchallenged data management opportunities, accurate operational decisions and reduces backlogs for data-driven manufacturing specialists.

Understand Smart Machine Competencies Transparently

Having better insights into smart assets can also help manufacturers in minimising the overall total cost of ownership of non-financial assets of the production or warehouse facility. It improves the safety of the manufacturing assets and enables effective predictive and prescriptive maintenance approaches to ensure that manufacturing devices and machines are in their best state- both conditionally and structurally. Data extracted by early detection sensors and other asset security technologies can help manufacturing asset operators to keep smart assets under close supervision and ensure there is no unscheduled breakdown, threat or risk that can affect the productivity, operational excellence and competitive advantage of the manufacturer.

Cerexio Manufacturing Technology Powered by Smart IIoT Integration

Cerexio is one of the few competent technology solution enablers that offer new-age technology solutions for smart machine-oriented manufacturers of the new age. We offer optimal PLC and instrumentation services to help your manufacturing team get the best out of your organisational data with minimal effort. Moreover, Cerexio’s AGV Fleet Manager is a solution that helps you tailor an interface that allows you to control 1000+ AGV and UAV devices in one remote location. The data extracted from the elastic and reliable IIoT networks of your factory will be manipulated by this technology suite to empower smart dashboards, Digital Twins, Simulation Platforms, Asset Maintenance Models, Predictive analytics Tools, Asset Security Protocols, Event-driven Process Scheduling and many more options. Connect with Cerexio to inquire more about this exclusive IIoT-driven technology suite for optimal remote smart machine control.

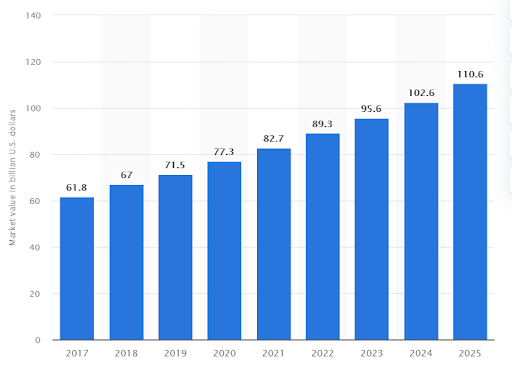

Imperatives That IIoT-driven Smart Machine Integration Belongs to The Future than The Current

The advancement of IIoT-driven smart and integrated fleet systems in the manufacturing world allows domain experts to reimagine and witness the dawn of a new level of manufacturing excellence. With time, manufacturers will gain the opportunity of capitalising on data value to optimise service-based offerings and pay-per-use financial models that benefit organisations and clients mutually. Centralised control, prediction of impending machine failures, strategic calibration of manufacturing processes based on events and many more smart decisions are all achieved in a shared effort with this technological advancement. Therefore, manufacturers of today must fear to meet the future today.