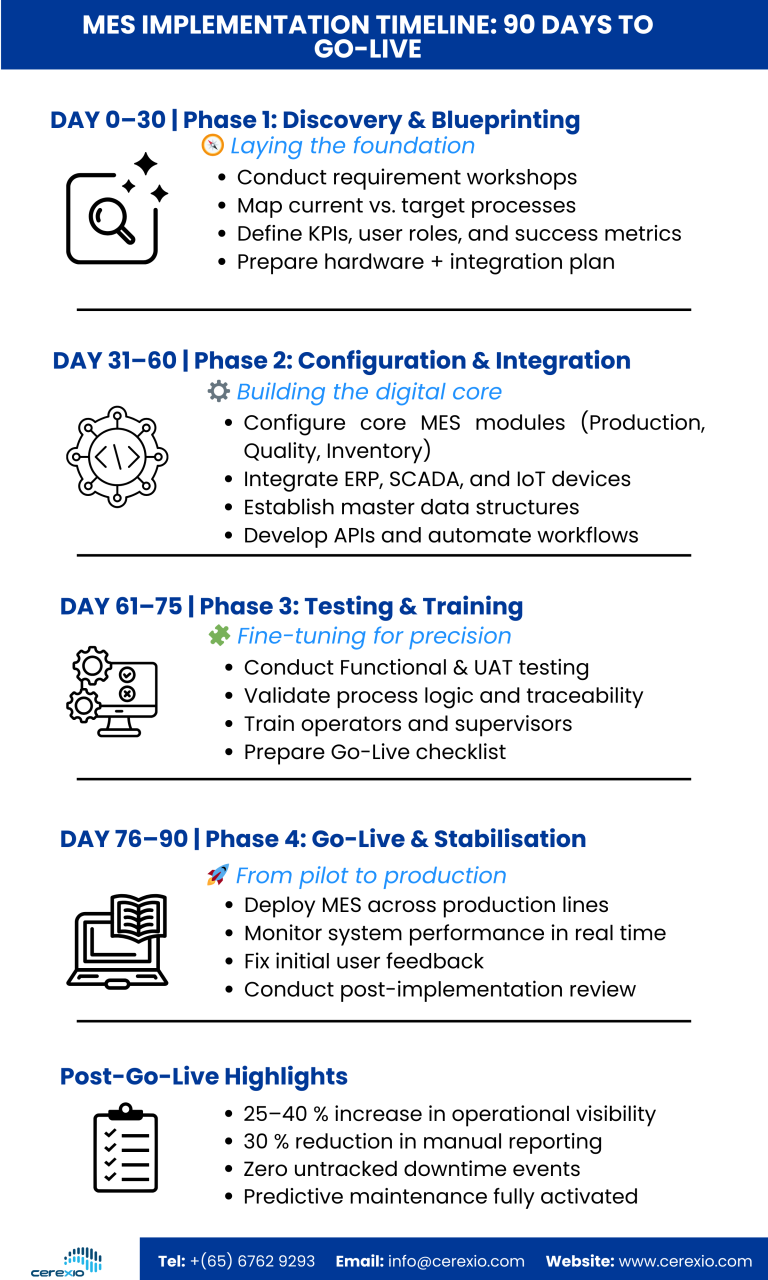

Implementing a Manufacturing Execution System (MES) doesn’t have to be a long, disruptive journey. With the right structure, clear milestones, and strong collaboration between business and technical teams, organizations can achieve measurable results in as little as 90 days. A phased MES implementation approach ensures that each stage builds on a solid foundation—starting with discovery and blueprinting to align requirements, KPIs, and processes, followed by configuration and integration to connect production, quality, inventory, ERP, and shop-floor systems. Rigorous testing and hands-on training then help validate workflows, ensure traceability, and prepare users for real-world operations. Finally, a controlled go-live and stabilization phase allows manufacturers to transition confidently from pilot to full production, while closely monitoring performance and addressing early feedback. The outcome is faster operational visibility, reduced manual reporting, improved data accuracy, and a strong platform for advanced capabilities like predictive maintenance and continuous improvement. Whether you are modernizing legacy systems or scaling digital manufacturing initiatives, a clear, time-bound roadmap is critical to success. To help visualize this journey and understand what happens at each step, we’ve summarized the entire 90-day MES implementation roadmap in the infographic below.