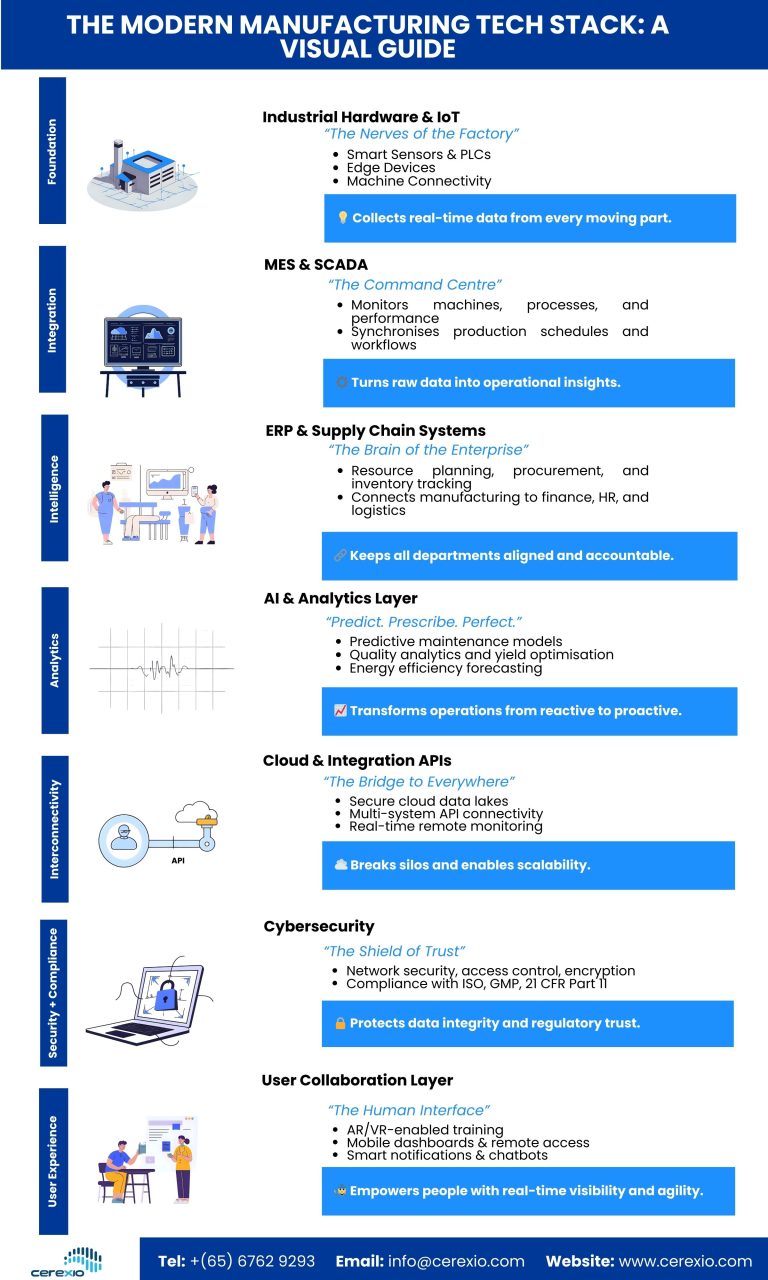

Modern manufacturing is no longer driven by a single system or technology—it’s powered by a carefully layered technology stack that connects the shop floor to enterprise decision-making. At the foundation, industrial hardware, sensors, PLCs, and IoT devices act as the nervous system of the factory, capturing real-time data from every moving part. This data flows into MES and SCADA platforms, which function as the command centre, monitoring machines, synchronising workflows, and translating raw signals into operational insight. Above that, ERP and supply chain systems provide the enterprise brain, aligning production with finance, inventory, procurement, HR, and logistics to keep the entire organisation accountable and in sync. The real leap forward comes with the AI and analytics layer, where predictive maintenance, quality optimisation, and energy forecasting transform operations from reactive to proactive. Cloud platforms and integration APIs then break down silos, enabling scalability, remote monitoring, and seamless data exchange across systems and sites. Cybersecurity underpins the entire stack, protecting data integrity and ensuring regulatory compliance, while user collaboration layers—such as mobile dashboards, AR/VR training, and smart notifications—put actionable intelligence directly into people’s hands. Understanding how these layers fit together is essential for building resilient, future-ready factories. To make this structure easy to understand at a glance, we’ve illustrated the modern manufacturing tech stack in the infographic below.