The modern floating manufacturing market, which is reaching US$14.26 trillion in 2026, is no longer about speed but about accuracy, consistency, and reliability. Whether it is an aerospace engine or a life-saving medical implant, the slightest variation can result in catastrophic failure. Here is where precision manufacturing is more than a production technique; it is a strategic advantage.

Advanced machines, data-driven control, and stringent quality regimes can deliver unparalleled performance and trust.

In this article, let’s explore how precision manufacturing works and what tools are driving this process, which is reshaping industry standards around the world.

We will discover

- What Is Precision Manufacturing?

- What Are the Core Technologies in Precision Manufacturing?

- How Does CNC Machining Enable Precision Production?

- What Other Precision Manufacturing Processes Are Essential?

- How Do Quality Control Systems Ensure Manufacturing Precision?

- What Are the Critical Quality Management Standards?

- How to Implement Effective Precision Manufacturing Quality Control?

- What Role Does Metrology Play in Precision Manufacturing?

- How Is AI and Machine Learning Transforming Precision Manufacturing?

- What Are the Key Industry Applications of Precision Manufacturing?

- What Challenges Exist in Maintaining Precision Manufacturing Standards?

- How to Optimise Precision Manufacturing Operations?

- Why Choose Cerexio for Precision Manufacturing Solutions?

- FAQs About Precision Manufacturing

What Is Precision Manufacturing?

High-precision manufacturing is the production of goods that have high precision, either in dimensions or performance. It brings engineering discipline, the consistency of precise machines, and rigorous quality control to deliver reliable results.

Key Takeaways

- High-precision manufacturing enables high accuracy, repeatability, and reliability in complex industrial production.

- To maintain tight tolerances and produce high-quality results, CNC, automation, and artificial intelligence play vital roles.

- Robust quality control systems and metrology help ensure compliance and minimise defective outputs while maintaining production.

- Precision manufacturing is crucial for industries such as aerospace, medical, and automotive to meet safety, performance, and regulatory production standards.

Defining Precision Manufacturing and Its Fundamental Principles

Precision manufacturing refers to fabricating parts that have dimensional accuracy, constant repetition, and controlled variation. It is based on well-controlled manufacturing processes, steady equipment, and well-kept records to verify that all the parts that have been produced comply with certain requirements.

This mechanism works through accuracy, repeatability, and process stability.

The Evolution From Conventional to Computer-Controlled Manufacturing

Manual skill was a very big part of early machining. This is where the introduction of computer numerical control (CNC) led to production machinists and die makers being replaced, with machining operations also being substituted for handwork.

This development minimised the probability of human error and ameliorated repeatability. Plus, this allowed companies to expand their complicated manufacturing while still preserving standards in accuracy.

Why Precision Engineering Drives Modern Industrial Excellence

Precision engineering techniques improve manufacturers’ ability to comply with rigorous performance, safety, and regulatory requirements. At this juncture, high-precision parts provide production quality and reduce dependence on rework.

Not to mention this helps to extend product life. Industries today rely on precision engineering for reliability, compliance, and competitive differentiation in international markets.

What Are the Core Technologies in Precision Manufacturing?

Precision manufacturing works around networked digital technology that delivers accuracy, automation, and control to the process. These solutions complement each other to provide consistent results in the most demanding production environments.

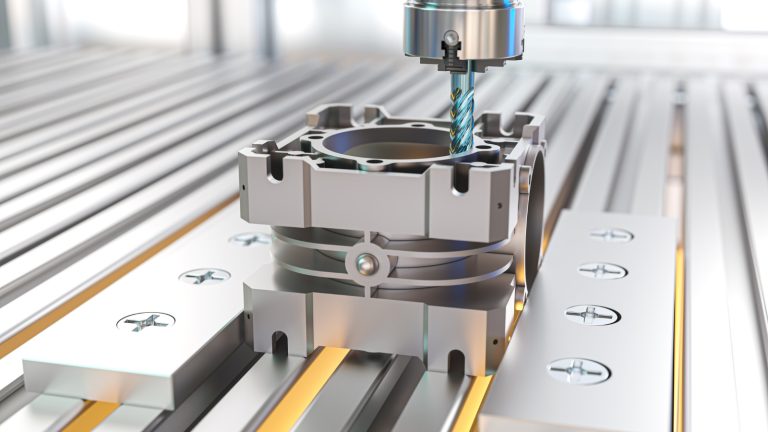

Computer Numerical Control (CNC) Machining Fundamentals

CNC machining processes involve manipulating the direction and speed of cutting tool movements using programmed tools. CNC systems provide identical part geometry, part-to-part repeatability, and the ability for near infinite production without a loss in product quality.

This technology has the power to accommodate elaborate designs while still meeting the tight tolerance manufacturing in high-performance industrial sectors.

Computer-Aided Design (CAD) and Manufacturing (CAM) Integration

Computer-aided design and CAM integration can link digital product models directly to machine tools, robots, and other production systems. With this strength, engineers can design a virtual tooling path and test parameters to minimise errors before the part goes on the machine. Furthermore, this digital continuity increases the precision of your work and facilitates production setup whilst enabling efficient design-to-manufacture processes.

Advanced Automation and Robotic Systems for Precision Work

Robotic handling and sensors allow advanced manufacturing automation to restrict variation in repetitive tasks. Automated systems to stabilise production conditions, reduce the work, and guarantee product yield.

Moreover, these systems are vital in large-scale and complicated manufacturing for maintaining accuracy.

How Does CNC Machining Enable Precision Production?

CNC processes are the workhorses of contemporary precision production. It supports intricate designs, tight tolerances, and material selection with a variety of options, yet allows for repeatable precision in low or high-volume use.

Multi-Axis CNC Capabilities for Complex Geometries

Multi-Axis CNC machines cause tools to move along more than one axis simultaneously, allowing intricate and undercut shapes to be manufacturedin a single setup. These advanced machining capabilities minimise repositioning error and ensure dimensional accuracy.

Apart from that, they can produce complex parts for high-performing industries.

Achieving Tight Tolerances Within ±0.001" Specifications

To hold such tight tolerances within ±0.001″, machinery stability, environmental control, and cutting parameters must be controlled to the maximum extent possible. It is possible to monitor tool paths and speeds using CNC systems.

It helps reduce variability in production runs and supports tight tolerance manufacturing requirements.

Material Versatility From Metals to Advanced Composites

You may know that CNC machining is compatible witha diversity of materials, ranging from metals and plastics to composite materials. Knowledge of the material properties, such as hardness and thermal properties, allows for modifying tooling and speeds.

Also, it helps maintain accuracy with the resulting optimal surface finish or performance.

What Other Precision Manufacturing Processes Are Essential?

In addition to CNC machining, we can see that other precision processes also contribute to ultrafine finishes, intricate forms, and production demands on the modern cutting tools that traditional tools are not capable of doing efficiently.

Precision Grinding for Ultra-Fine Surface Finishes

The high-resolution grinding process is capable of removing sub-micron material up to several microns of metal gaskets and surface, with enhanced Gyro Grinding geometry control. This is especially important when tight tolerances are crucial, and surface finish issues come into play.

Another thing is that grinding increases part functionality, lubricity, and equates to improved long-term wear in precision parts.

Electrical Discharge Machining (EDM) for Complex Geometries

Electro-Discharge Machining, or EDM in short, is a method to process hard materials that uses electric spark discharges, which occur due to intermittent direct contact. EDM is very good for designing complex pockets and maintaining machining operations accuracy.

It is perfect for hard metals and complex internal structures.

Laser Cutting and Additive Manufacturing Technologies

Laser cutting creates clean, high-precision cuts with little heat distortion, while additive manufacturing forms parts layer by layer. These methods enable fast prototyping, customisation, and design freedom as a complement to conventional precision methods for an extended capability of modern manufacturing processes.

How Do Quality Control Systems Ensure Manufacturing Precision?

Successful precision manufacturing relies on organised verification strategies to monitor variation and sustain consistent production. These controls involve data, inspection, and feedback to ensure they maintain accuracy throughout production.

Statistical Process Control (SPC) and Real-Time Monitoring

Statistical process control, or SPC, monitors trends in data to prevent variation from becoming a defect. This is where you can utilise real-time monitoring to stabilise the process, decrease scrap, and improve quality assurance.

This way, SPC allows operations to make pre-emptive changes. It ensures that nothing is out of specification by the time it is complete.

Coordinate Measuring Machines (CMM) for Dimensional Verification

A coordinate measuring machine checks part geometry by comparing its dimensions with the digital models. CMMs provide micron-level precision and repeatability, making them an indispensable part of complex component validation.

This type of system enables objective verification and minimises measurement error due to humans ina precision environment.

First Article Inspection (FAI) and In-Process Quality Checks

First Article Inspection verifies first-run parts before you produce them in large quantities. Together with the point checks as part of inspection methods, the in-process check guarantees that deviations are detected at an early stage.

This phased methodology provides you with more predictable results, minimises rework , and keeps confidence high throughout extended production runs.

What Are the Critical Quality Management Standards?

We know that product quality standards deliver organised templates to connect processes, documentation, and accountability. They exist to ensure that precision manufacturers adhere to regulations and keep their facilities and equipment in tip-top shape.

- ISO 9001:2015 Certification Requirements and Implementation

ISO certification under ISO 9001:2015 introduces documented information, risk-based thinking, and preventive action. Talking about the importance of certification, it means that a process discipline becomes stronger, traceability is improved, and customers can be assured that their production system at any time meets set quality objectives throughout operations.

- Six Sigma Methodologies for Defect Reduction

Six Sigma uses statistical analysis to firmly determine the cause or causes of defects and to standardise operations by eliminating process variance. Through virtually eliminating errors, Six Sigma improves quality and increases consistency, reduces waste, and enhances the ability to measure performance improvements in precision manufacturing environments.

- Industry-Specific Standards for Aerospace, Medical, and Automotive

You need stripped-out layers of compliance in heavily regulated markets above and beyond common sense. It is common for the aerospace, healthcare, and automotive industries to require stringent documentation, validation, and risk controls.

These are frameworks that manufacturers can utilise to validatethe safety and integrity of components, as well as comply with regulations for your mission-critical product.

How to Implement Effective Precision Manufacturing Quality Control?

As soon as quality control has to be applied in a precision context, the call for a structured thinking mode, controlled circumstances, and personnel becomes a must. These measures guarantee repeatable accuracy, comply with regulations, and provide process stability over the long term.

Step 1 – Establishing Quality Planning and Control Procedures

In reality, you can document the starting point for efficient quality control as planning that determines inspection points, acceptance criteria, and response activities. Clear processes bring teams around consistent execution, safeguard production quality, and establish accountability for all aspects through the manufacturing lifecycle.

Step 2 – Implementing Environmental Controls and Calibration Systems

Precision results are sensitive to environmental conditions. On the other hand, tight tolerance manufacturing is also sensitive to temperature, humidity, and vibration.

With the right equipment calibration, you can maintain measurement accuracy and machine reliability while output patterns are consistent throughout long production runs.

Step 3 – Training Personnel and Maintaining Documentation Standards

Quality requirements keep the necessity of skilled labour. At this point, continuous training assures that operators are familiar with processes, tolerances, and inspection criteria.

Solid documentation enables traceability, audits, and ongoing training within manufacturing that is in a state of flux.

What Role Does Metrology Play in Precision Manufacturing?

Metrology tools are the measurement bedrock upon which to prove microscopic accuracy. This guarantees all components will conform to established standards when downstream processes are targeted.

Advanced Measurement Techniques and Inspection Equipment

Metrology and inspection process leverage sophisticated sensors, laser scanners, andhigh-resolutionn probes to collect precision measurements. These gauges verify geometry, alignment, and surface finish to guarantee that manufactured components meet exacting tolerance demands throughout a myriad of process applications.

Environmental Control Requirements for Micron-Level Accuracy

Such a measurement at the level of a few microns requires highly stable operating conditions. Differences in temperature or vibration may skew results.

This is where the controlled labs and manufacturing floors maintain the dimensional accuracy required for trusted inspection results and validated performance.

Traceability Systems and Calibration Verification Processes

A measurement is traceable when it is related to references such as standards, instruments, and procedures. Moreover, calibration records can be cross-referenced between inspection systems to ensure accuracy.

These controls enable audits, compliance, and trust in long-term measurement reliability across the factory ecosystem.

How Is AI and Machine Learning Transforming Precision Manufacturing?

Precision manufacturing is being revolutionised through artificial intelligence and machine learning as predictive, adaptive, and highly efficient production systems are developed.

AI-Powered Defect Detection and Predictive Quality Control

Artificial intelligence finds subtle patterns in production data that can indicate future errors. When combined with predictive quality control, AI reduces waste, improves production quality,y and helps guarantee parts meet precise tolerances at the speed of real-time manufacturing.

Machine Learning for Process Optimisation and Efficiency Gains

Machine learning processes historical and live data to optimise tooling, cutting speeds, and material. Continuously tuning parameters provides manufacturers with better process optimisation, lower cycle time,s and increased production efficiency for complex machining operations.

Digital Twin Technology for Virtual Process Simulation

Manufacturers can employ Digital Twin technology to develop a virtual copy ofa factory’s processes and systems, which provides the opportunity for simulation or scenario testing without interfering with production.

This minimises errors, forecasts performance implications, and allows for quicker adjustments to ensure precision manufacturing remains nimble, accurate, and data-driven.

What Are the Key Industry Applications of Precision Manufacturing?

Precision Manufacturing drives innovation in fields where safety, performance, and compliance cannot be compromised.

Aerospace Components Requiring Critical Tolerances and Certifications

It is common knowledge that the manufacturing of aerospace components requires incredibly tight tolerances, which are rigorously checked by quality control systems. Parts have to adhere to rigorous certification standards and tolerances, for both safety and reliability in critical applications such as engines, turbines, and flight-critical structures.

Medical Device Manufacturing With Regulatory Compliance Demands

When it comes to medical implants and instruments, everything must be defined in detail and documented carefully. Regulatory conformance, repeatable dimensional accuracy, and high reliability of the medical devicesworkt together to accomplish patient safety andlong-termm device performance.

Automotive Precision Parts for Performance and Safety

The automotive industry uses precision-engineered components, including gears, brakes, and engine parts. At this point, strict surface finish requirements and tight tolerances deliver performance, longevity, and safety to minimise failures and warranty claims.

On the other hand, it supports production line throughput efficiencies.

What Challenges Exist in Maintaining Precision Manufacturing Standards?

Despite having a technology that is getting more sophisticated, precision manufacturing still contends with material responses, cost pressure, and the scaling of production.

Managing Material Variability and Thermal Expansion Effects

Materials react differently to temperature, stress, and machining. The manufacturing industry must consider material properties and related thermal expansion in order to work within these tight tolerances without violating the design and binding principles.

Balancing Tight Tolerance Requirements With Cost Constraints

Precision is expensive. This means that the higher you go, the more you must pay. This is where the manufacturers face pressure to balance precision engineering techniques with budgetary limitations.

That way, they can find the right balance in their practices and materials, which keeps them in business without losing their customers.

Ensuring Consistent Quality Across High-Volume Production Runs

Precision manufacturing at scale requires strong quality control mechanisms. In addition, constant and automatic inspections with real-time monitoring contribute to production quality control in large numbers of batches, decreasing defectives while increasing reliability.

How to Optimise Precision Manufacturing Operations?

Performance enhancements emphasise how to make precision manufacturing operationally more effective, cheaper, and flexible enough for future requirements. The key enablers are continuous improvement, smart technologies , and real-time data.

Implementing Continuous Improvement and Lean Manufacturing Principles

Methods such as lean manufacturing are based on the philosophy of continuous improvement processes that consist of waste elimination, workflow optimisation, and best practice continuity.

This promotes stable operation and improvement of production efficiency, reduction in defects, andmaintainsg consistent production quality in all manufacturing processes.

Leveraging Industry 4.0 Technologies for Smart Factory Integration

Sensors, IoT, and automation can be incorporated into production lines with the help ofthe Industry 4.0 ecosystem. Smart factories create the ability to do predictive analytics, better process control, and connected systems, which improve automation yet keep tight tolerance manufacturing scalable and flexible with market demands.

Utilising Real-Time Data Analytics for Proactive Decision-Making

Real-time analytics can reveal how equipment is performing, where the bottlenecks in a workflow are, and when quality has gone out of scope. Manufacturers get immediate results and can make real-time decisions to optimise machining operations, reduce downtime, and improve defect detection, affecting a proactive production rather than a reactive one.

Why Choose Cerexio for Precision Manufacturing Solutions?

CerexioTechnologies simply combines leaders with the latest global resources to offer customers the best in precision-manufacturing experience. Focused on the future of accuracy, efficiency and visibility in modern precision manufacturing, Cerexio becomes the best solution for your manufacturing concerns.

Advanced IQ/OQ Systems for Validation and Quality Assurance

Cerexio’s IQ/OQ system verifies equipment, processes, and software in accordance with regulatory requirements. These implements are used to support quality control systems, ISO certification, and the production of consistent, repeatable quality.

Track and Trace Capabilities With Complete Production Visibility

The Cerexio Track and Trace system allows manufacturers to trace every piece from raw material through all manufacturing processes. This increases accountability, allows swift corrective action, and is compliant with industry-specific standards in aerospace, medical and automotive markets.

AI-Powered Manufacturing Control Tower for Precision Optimisation

The AI-powered Cerexio Manufacturing control tower combines predictive maintenance, machine learning, and process optimisation. Manufacturers will be able to predict variances, ensure maximum uptime and tight tolerances for operational excellence in high-volume and high-precision production.

Ready to Elevate Your Precision Manufacturing Capabilities?

Move toward the next generation of smarter, more accurate and efficient production with the Cerexio expertise.

Consult With Cerexio Precision Manufacturing Experts

Cerexio experts offer customised support to facilitate the implementation of precision engineering processes, automation, and quality programmes. Their experience and knowledge guarantee that your manufacturing company achieves significant increases in the areas of production efficiency and accuracy, regardless of the process.

Discover How Smart Systems Can Improve Quality by 50%

You can also improve the quality of production with AI, digital twins and integrated quality control systems. By eliminating errors, optimising workflows and enabling the enterprise-wide exchange of ideas from ideation to production, Cerexio smart systems can lead to as much as a 50% improvement in manufacturing consistency.

Call for a free demo today.

Cerexio-Transform Your Operations With Cutting-Edge Precision Technologies

FAQs About Precision Manufacturing

Precision manufacturing is a production approach that delivers high-dimensional accuracy, repeatability, and low variation through advanced technologies such as CNC machining, automation, and quality control. It ensures parts meet exact specifications, improves reliability, and reduces waste across critical industries such as aerospace and medical devices.

Precision manufacturing matters because it improves product quality, reduces defects, and accelerates production efficiency. By achieving consistent, tight tolerances and minimising errors, manufacturers strengthen competitiveness, reduce costs, and unlock innovation opportunities in complex, high‑performance applications.

By using automated systems, digital workflows, and real‑time monitoring, precision manufacturing maintains exact specifications across production runs. This reduces variation, minimises scrap, and delivers parts that consistently perform as expected, boosting customer confidence and reducing rework.

Precision manufacturing uses technologies like computer numerical control (CNC), CAD/CAM integration, robotics, and automated inspection systems. These tools provide consistent accuracy, support complex geometries, and enable scalable output while improving control and reducing manual errors in production.

Industries such as aerospace, medical devices, and the automotive industry benefit greatly from precision manufacturing. Their components require strict tolerances, regulatory compliance, and high reliability, making precise production essential for safety‑critical and high‑performance applications.