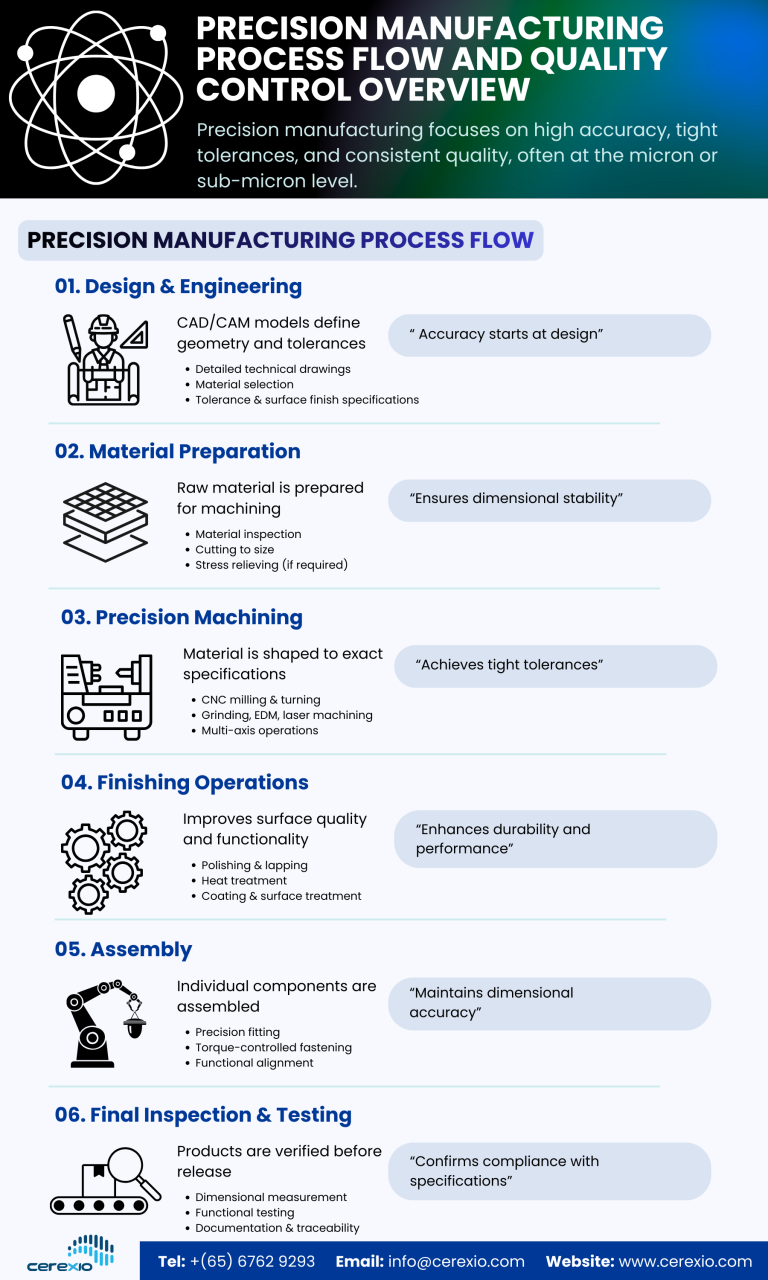

Precision manufacturing is built on accuracy, tight tolerances and uncompromising quality standards, often measured at micron or even sub-micron levels. In industries such as aerospace, medical devices and advanced engineering, even the smallest deviation can impact performance, safety and compliance. Achieving this level of precision requires a carefully controlled process flow, beginning with detailed design and engineering, followed by material preparation, high-accuracy machining, finishing operations, assembly and rigorous final inspection. Each stage plays a critical role in maintaining dimensional stability and ensuring specifications are met consistently. Quality control is not a final step but an integrated discipline embedded throughout the entire workflow. By combining advanced machining techniques with structured inspection and traceability, manufacturers can reduce defects, improve reliability and enhance overall product performance. To understand how each stage contributes to consistent, high-quality output, learn more by reading the infographic below.