We have entered 2026, and global manufacturers still face supply chain issues. If you are from the manufacturing industry, your team has a toolbox full of new and shiny analytics tools and techniques you learned from the last disruption, but pressure is high from global conflicts, labour shortages, and changing customer demands, right?

Being aware of the most common and top supply chain challenges and taking action to navigate them is necessary for your operation to stay efficient, keep costs down, and satisfy customer expectations.

The guide below looks at the top 10 supply chain issues manufacturers will confront in 2026, what caused them, and how you can toughen your supply chain resilience.

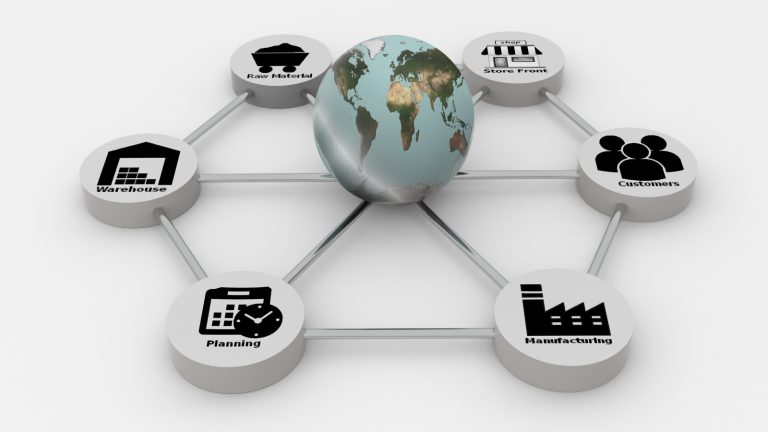

What Are Supply Chain Issues?

We all agree that supply chain issues are critical to manufacturers looking to stay effective and profitable. These interruptions can occur from the very start, with raw material sourcing, through to final delivery, affecting production, logistics, and customer service.

This is where knowing the root causes of an issue enables you to develop plans to mitigate operational risks.

Supply chain issues may result from:

- Shortages of raw materials

- Limitations in the labour and workforce aspects

- Logistical challenges

- Regulatory compliance bottlenecks

- Gaps in technology adoption

Do you know the scariest part? Not being dealt with, these challenges can lead to more expensive use of money, delayed schedules, and less income. Therefore, mastering risk management is crucial.

Key Takeaways

- Manufacturers in 2026 face increasing challenges in their supply chains due to geopolitical uncertainty, employee shortages and higher costs, and high customer expectations.

- Solving these would need strategic inventory plans, sourcing that is diversified, adoption of technology, and logistics optimisation.

- The adoption of Industry 4.0 technologies like AI, digital twins, and real-time analytics allows for more visibility, resilience, and flexibility along the supply chain.

- Opting for digital solutions enables you to get ahead of disruptions, increase efficiency, and prepare for the future in a manufacturing supply chain.

Top 10 Supply Chain Issues Affecting Manufacturers in 2026

There are many headwinds for manufacturers in 2026 that could threaten to disrupt business and stagnate production. These supply chain challenges, ranging from geopolitical unrest to labour shortages, require active solutions.

If you can pinpoint your organisation’s top 10 pain points, focus on prioritising the activities that protect against those challenges and ensure competitiveness.

Global Political and Geopolitical Unrest: How Conflicts Disrupt Your Supply Chain

No need to mention that global political instability is among the most unpredictable risks shaping your supply chain in 2026. Wars, trade bans, and diplomatic spats can block the shipment of raw materials or finished goods, and then the Chinese factory’s output hits a hiccup in production.

Companies that source from one country are especially vulnerable, as border closings or export bans can disrupt their supply chains. Not just major policy shifts but even small ones in major trading regions could have cascading effects throughout your logistics network.

Further, diversification of suppliers, tracking political events, and carrying stock of vital materials can limit these risks. This is when your proactive approach means your production will not be endangered, and your supply chain solution will remain robust in the face of international disruptions.

Rising Energy and Fuel Costs: Strategies to Minimise Impact

Energy and fuel prices continue to burden manufacturing budgets, and the cost of shipping across logistic operators in 2026. Volatility in oil and gas prices adds cost to transporting products, running equipment, and holding inventory.

Moreover, these costs can erode profit margins for manufacturers, especially as operational expenses are already rising due to global supply chain delays. Conserving energy by implementing efficiency measures, purchasing energy-efficient technologies, and being strategic in the planning of transportation needs can all add up to a dramatic impact.

Other manufacturers are looking at alternative fuels like solar or biofuels, while others combine shipments to reduce transportation costs. No doubt, managing energy costs ahead of time helps maintain overall supply chain optimisation and keeps your business competitive and sustainable, without creeping costs.

Increasing Consumer and B2B Expectations: Meeting Demand Efficiently

Your customers’ expectations in 2026 are higher than ever, serving other businesses or end consumers. Have you already sensed it?

Buyers demand instant delivery, full disclosure, and friction-free service, and they often want their orders yesterday. What’s more, falling short of these customer satisfaction requirements may cause damage to your brand and loss of market share.

The manufacturers must respond to demand forecasting and inventory tracking to ensure deep, transparent shipments right along the way. The proactive communication in the event of delays and accurate delivery windows plays an instrumental role in establishing trust and loyalty.

There will need to be a happy equilibrium between demand and cost, where an agile supply chain response can quickly respond to ramp-ups and downs in consumer demand while delivering for both the convenience of delivery and business efficiency.

Labour Shortages and Workforce Management: Overcoming Staffing Challenges

In 2026, there will remain shortages of manufacturing and logistics labour that act as bottlenecks across production, warehousing, and transportation. Deloitte estimates the industry could need up to 3.8 million new workers by 2033, though close to half of these (1.9m) could go unfilled.

Operators, logistics managers, and drivers are in short supply, and recruitment and retention are at the forefront. Such scarcities can cause production schedules to slow, overtime costs to rise, and overall productivity to decline.

At this juncture, firms must be willing to retrain existing workers and consider using temporary staff while they invest in automation for routine jobs. By introducing robotics, AI-supported scheduling, and digital monitoring solutions, you can continue to produce efficiently even with significantly fewer people.

By taking proactive steps to confront your challenges, this is how you can make your supply chain solutions stronger and ensure that labour will not inhibit your business.

Supply Chain Cybersecurity Risks: Protecting Your Digital Operations

In this era, manufacturers will hold hands with cybersecurity, more automation, and digital supply chain technologies due to increasing threats on virtual platforms. Cybersecurity breaches, ransomware attacks, and system outages can cause production to cease, shipments to be delayed, and sensitive business information to be compromised.

This can quickly cause failure and have a knock-on effect on suppliers and customers worldwide from your operations. Strong cybersecurity, encryption of communications, multi-factor authentication, and continuous system monitoring are key to guarding your supply chain optimisation.

However, you need to keep in mind that the training of employees in cyber hygiene and regular IT audits is just as important. If you could protect your software supply chain, you could protect manufacturing by not unnecessarily exposing your factory to threats.

Regulatory Compliance and ESG Requirements: Staying Ahead of Legal Changes

From this year, pressure of regulations and ESG (environmental, social, and governance) further transforms supply chains. Manufacturers are subject to environmental laws, labour requirements, and otherwise fair trade rules as expectations for sustainability continue to evolve.

Fail to do so, and you may end up with financial penalties, legal exposure, and a poor public image. It is complex but also critically important: You need the ability to monitor emissions, manage supplier audits, and report on compliance across geographic regions.

And integrating ESG elements into procurement, production, and logistics can increase operational resilience and strengthen a brand. With the adoption of sustainable business practices to save energy, use more responsible sourcing, not only have you mitigated exposed risk but also demonstrated that you are forward-looking and responsible organisations.

These steps are strengthening supply chain solutions and fostering trust among customers and suppliers.

Transportation and Logistics Constraints: Avoiding Delivery Delays

As per the experts, in 2026, manufacturers will still be dogged by transportation bottlenecks and logistics constraints. Congestion in ports, tightness in trucking capacity, and delayed shipping schedules can disrupt production lines and create delays for customers.

Add to that the increasing need for speedy shipping, and those limitations are only heightened, even as they place more demands on your system. This is where the vendors need to plan ahead with shipments, consider multi-modal transportation, and maintain strong relationships with a couple of carriers to ensure they are keeping reliable.

Continuous logistics in online measuring allows immediate changes to be made in order to avoid bottlenecks and save costs. By routing and consolidating shipments more effectively, while preparing for what-if scenarios, you can more efficiently keep goods flowing from suppliers to plants and customers.

Is it necessary to say that it bolsters your supply chain optimisation along with overall operational resilience?

Raw Material Shortages: Securing Your Production Inputs

Shortages of key raw materials remain an ongoing challenge for manufacturers in the future as well. We can stop machines and impact delivery times if a supply chain is interrupted from geopolitical maneuvering, a natural disaster, or fulfillment centers that struggle to keep up with demand.

Dependence on one supplier is likely to render communities more vulnerable in the event of such disruptions. In order to reduce risk, vendors need to diversify supply chain options and buffer inventory while finding other sources elsewhere or locally.

That is why it says that close working relationships with suppliers and joint forecasting help guarantee that necessary parts are delivered on time.

Proactively managing raw material supply to ensure a reliable production schedule and satisfied customer demand, while capturing supply chain benefits. This strategy stabilises your operations amidst global variability in the raw materials market.

High Product Return Rates: Reducing Operational Strain

Too many returns of product can mess your inventory, increase costs, and stretch the manufacturing-supply chain to its whirling limit. It is high-quality product information, quality control, and clear guidance to the customer that can save return rates.

Returns cause inefficiencies from reverse logistics processing, labour, and storage that can slow the velocity of production and shipment. However, manufacturers can optimise supply chain efficiency through sharing detailed specs, demo videos, and 360 product images, which help align expectations.

Facilitating reverse logistics, providing in-store returns, or offering low return fees further eases the burden. Reducing the number of returns on products comes with a grim reminder that profitability is maximised, and your supply chain optimisation will be increased. Plus, you can use the resources to their optimal potential, and your customers will be satisfied.

Lack of Supply Chain Digitisation: Embracing Technology for Efficiency

In 2026, manual or legacy systems-based manufacturers will have difficulty being visible and agile with their practices. Without the integration that current digital technology provides, real-time inventory control and production and logistics monitoring are impossible, which means delays and increased costs.

However, you can implement supply chain management software, AI-driven demand forecasting, and IoT-based monitoring for faster decision-making and better visibility in operations. Further, you can opt for automated warehouse systems, predictive analytics, and digital tracking as they streamline production and logistics for manufacturers. That way, you can be more proactive in responding to disruptions.

As you can see, digitisation will improve overall supply chain optimisation, eliminate human oversight, and increase speed while keeping your operations resilient, agile, and competitive in an ever-changing global market.

4 Proven Steps to Strengthen Your Supply Chain in 2026

Despite ongoing difficulties, your manufacturing company can have the tools to minimise disruption and keep operations running smoothly.

Hold Strategic Inventory Buffers

Mediating the effect of supply chain disruption 2026 depends on having the right inventory level. You optimise inventory by looking at historical sales cycles and predicting so you have the right amount of stock available on hand for customers, but not too much.

Strategically, you get to keep inventory buffers, avoid any costly delays in production, and drive better supply chain optimisation.

Diversify Supplier Base

Being dependent on a single vendor makes you more susceptible to supply chain issues. You also spread your risk when you source materials from many countries and establish close partnerships.

This is where diversification delivers reliable production flow, back-up production capabilities in the event of geopolitical or environmental disruption. This strategy simply reinforces your supply chain solutions to support long-lasting manufacturing resilience.

Implement Advanced Technology Solutions

Turning to technology is a necessity for today’s manufacturers in order to deal with supply chain challenges. However, it is a wise approach to digitise processes (workflows), implementing AI for demand forecasting, and connecting IoT devices to keep track of inventory and production live.

These solutions provide visibility, accelerate decisions, and improve supply chain optimisation that enables proactive management of these disruptions.

Optimise Logistics and Transportation

Effective logistics planning is the solution for surviving a supply chain breakdown 2026. It is time to leverage multi-modal and consolidated shipments and multiple carriers to reduce gridlock.

Proactively planning for changes such as port restrictions or other transportation limits, meaning shipments are made on time, with reduced costs. This demonstrates that your supply chain solutions continue to be a strong and reliable solution for operations.

How Cerexio WMS Empowers Manufacturers to Overcome Supply Chain Challenges in 2026

CerexioWMS is a highly robust Industry 4.0-enabled Warehouse Management System that will help you reimagine your complex manufacturing supply chains and gain control, visibility, and resilience in them. It solves today’s supply chain disruptions by using a solution based on automation, real-time data, and intelligent analytics.

Intelligent Inventory and Warehouse Optimisation

Cerexio WMS allows you to quickly manage inventory through instant visibility, intelligent slotting, and demand-based replenishment. With Industry 4.0 tools like IoT and analytics, you minimise stockouts, prevent overstock, and maximise warehouse productivity in the face of persistent supply chain challenges.

End-to-End Visibility and Disruption Resilience

Our software solution provides you with real-time supply chain visibility with centralised dashboards, automation, and system integrations. You can mitigate against delays, shortages of workers, and logistics issues by proactively identifying disruptions in the supply chain to optimise your supply chain’s efficiency as well as protect your manufacturing operation from supply chain issues in 2026 and beyond.

Call for a free demo today.

Tackling Supply Chain Issues Strategically

If you are a manufacturer in 2026, solving supply chain issues is a priority to remain competitive. From geopolitical tensions and energy costs to digitisation and workforce challenges, every challenge needs a forward-looking response. How you can stay afloat is through diversifying suppliers, digitalising operations, managing inventory wisely, and using technology to help you make it through disruptions and keep producing to meet your customers’ needs.

With an emphasis on supply chain resilience and optimisation, you will certainly be able to minimise risk, enhance your brand, and enable growth that stands the test of time in a volatile global market.

FAQs About Supply Chain Issues

The main causes of supply chain disruption 2026 include geopolitical unrest, labour shortages, rising fuel and energy costs, regulatory changes, and heightened consumer expectations for faster delivery. These factors combine to create complex supply chain challenges that manufacturers must address to maintain efficient operations and prevent costly delays.

Manufacturers can reduce transportation delays by implementing multi-modal logistics, using air, sea, and rail transport strategically. Diversifying shipping partners and maintaining inventory buffers ensures continuity during disruptions. These steps improve supply chain optimisation and minimise the risk of production downtime caused by delayed shipments or logistical bottlenecks.

Digitising your supply chain provides real-time visibility, predictive analytics, and automation, allowing faster, data-driven decisions. For manufacturers, this reduces risks associated with supply chain disruption 2026, optimises inventory management, enhances operational efficiency, and strengthens overall supply chain solutions, ensuring smoother production and delivery processes.

Labour shortages directly impact production capacity, delaying manufacturing and shipping schedules. Manufacturers must increasingly rely on automation, workforce training, and process optimisation to maintain efficiency. Addressing labour constraints is essential for supply chain optimisation, reducing vulnerability to disruptions, and sustaining the timely delivery of products to customers and business partners.

High product return rates strain your supply chain and inventory management. Clear product descriptions, detailed visuals, instructional manuals, and efficient reverse logistics systems help reduce returns. Implementing these strategies enhances supply chain efficiency, minimises disruptions, lowers costs, and ensures your manufacturing operations remain streamlined despite rising customer expectations.