This article will explore how to effectively utilise warehousing robotics in smart manufacturing, revealing new horizons for all the manufacturers in Singapore.

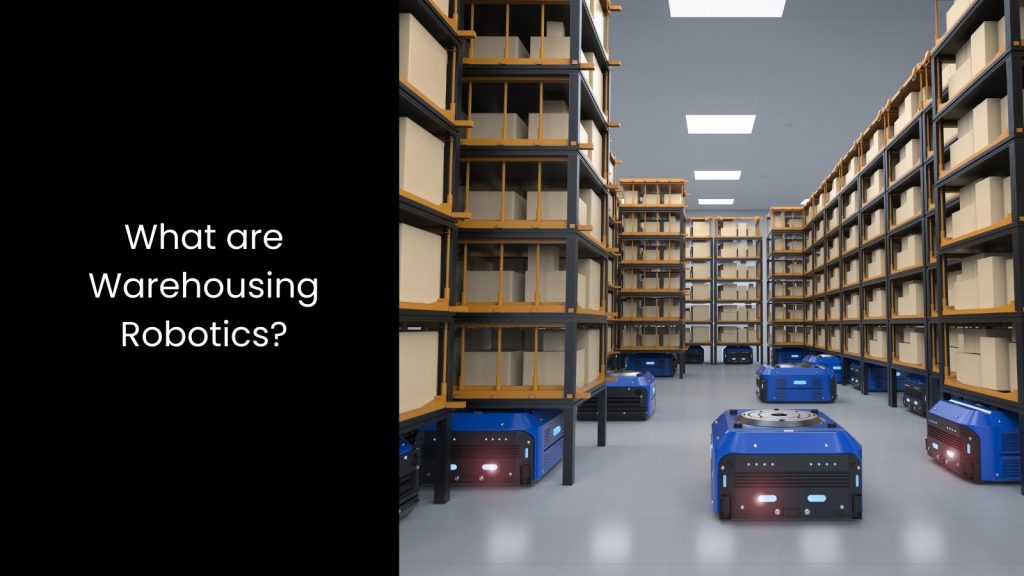

What are Warehousing Robotics?

- As of 2023, over 50% of warehouses globally use robotics to streamline operations. This shows how rapidly these technologies have become integral in manufacturing. Do you agree?

- Warehousing robotics is basically the use of automated machines to handle tasks such as sorting, transporting, packing, and inventory management within warehouse environments. If we fly back to the roots, robotics has been introduced to manufacturing warehouses to address several challenges, including labour shortages, the need for higher efficiency, and rising operational costs. The problem was that traditional warehouse setups usually rely heavily on manual labour to move goods, track inventory, and fulfil orders, which can lead to errors, slower processing times, and increased costs. Going beyond that, warehousing robotics allows businesses to automate repetitive tasks, increasing speed and accuracy while reducing human error.

- How this technology is unique is the number one question to be solved. This differs from normal robotics in its design and purpose. While traditional industrial robots might focus on manufacturing processes like assembly or welding, warehousing robots specialise in handling goods, navigating large storage spaces, and working with inventory systems. They have features like sensors, AI, and machine learning capabilities that enable them to adapt to their environments and optimise their operations based on real-time data. This contrasts sharply with traditional setups, where workers manually complete these tasks.

- Moreover, normal robotics often function in fixed positions, while warehousing robots like autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) can move freely within warehouses. The rise of smart manufacturing in many countries, including Singapore, has driven the need for warehousing robotics as they can integrate with larger systems, providing real-time data and analysis that helps improve decision-making.

- This is a remarkable shift in the manufacturing domain.

Top 6 Ways You Can Use Warehousing Robotics in Smart Manufacturing

Collaborative Robots (Cobots)

Unlike traditional robots, which often need separate spaces for safety, cobots can safely operate alongside workers, improving efficiency in warehousing and manufacturing. Also, Cobots can work alongside human workers to complete tasks that require precision or physical strength, enhancing safety and productivity.

In smart manufacturing plants, cobots enhance operations by handling jobs that are too dangerous or physically demanding for humans, such as lifting heavy materials or performing repetitive movements like packaging. This support allows human workers to focus on more complex tasks while reducing fatigue and injury.

Loading and Unloading Trucks

As we mentioned before, these robots use advanced sensors, AI, and machine learning to handle large volumes of goods quickly and efficiently. In traditional setups, human workers manually load and unload items, which can be time-consuming and physically demanding. Warehousing robotics automates this process, reducing the need for manual labour and minimising the risk of injuries caused by heavy lifting or repetitive movements.

Since it is possible to automate these tasks, robotics increases productivity and ensures goods move through the supply chain faster.

Order Picking and Packing

This technology can efficiently handle order picking, reduce labour costs, and increase speed and accuracy in the fulfilment process. Traditionally, human workers manually pick items from shelves and pack them, which can be time-consuming and prone to errors. Warehousing robotics automates this process by using advanced sensors and software to locate and pick items with precision.

These robots can quickly move through the warehouse, retrieve products, and deliver them for packing, ensuring faster order fulfilment. As it reduces the reliance on human labour, businesses save on operational costs while minimising the risk of mistakes. Additionally, robotics ensures consistent performance even during peak demand periods, helping companies meet customer expectations for faster deliveries.

Material Handling and Transport

Robots can move materials between storage and production areas, minimising manual labour and streamlining internal logistics. Warehousing robotics automated material transport using advanced navigation systems and AI, allowing robots to quickly and safely move items across the warehouse.

This reduces the risk of accidents, improves speed, and frees up human workers to focus on more complex tasks.

Quality Control and Inspection

Manual inspections are time-consuming, especially when dealing with large volumes of products, and workers can miss subtle defects due to fatigue or oversight. This can compromise the quality of the final output, leading to customer dissatisfaction or costly recalls.

However, robots equipped with sensors can inspect products for defects, ensuring high-quality output without human intervention. In smart manufacturing, warehousing robotics automates the inspection process, using advanced sensors, cameras, and AI to detect even the smallest defects in products. These robots work faster and more accurately than human workers, ensuring consistent quality across all items.

Automated Sorting Systems

When it comes to robotics, this technology can automatically sort products based on size, weight, or destination, enhancing the efficiency of sorting operations. With warehousing robotics, manufacturers can streamline sorting processes by using robots equipped with sensors and AI to quickly categorise and direct products to the right locations. These robots operate faster and more accurately than human workers, reducing mistakes and speeding up the overall workflow.

It is unnecessary to say that automated sorting also helps optimise warehouse space, ensuring that products are organised and easy to locate.

Cerexio Powered AGV Technology for Better Manufacturing Experience

Cerexio’s powered Automated Guided Vehicle (AGV) technology-embedded Smart WMS software solutions enhance your manufacturing experience as they automate material transport and streamline workflows. These AGVs navigate autonomously, optimising movement between production lines, storage areas, and loading docks. With advanced sensors and AI, Cerexio’s AGVs improve efficiency, reduce labour costs, and minimise errors in material handling. This technology ensures timely deliveries and keeps your customers satisfied.

Simplifying Smart Manufacturing Workload with Warehousing Robotics

The journey toward smart manufacturing becomes smoother with warehousing robotics as it transforms challenges into opportunities for growth. If you opt for these innovative solutions, you can create an efficient workspace where effectiveness and profitability reign beyond doubt.