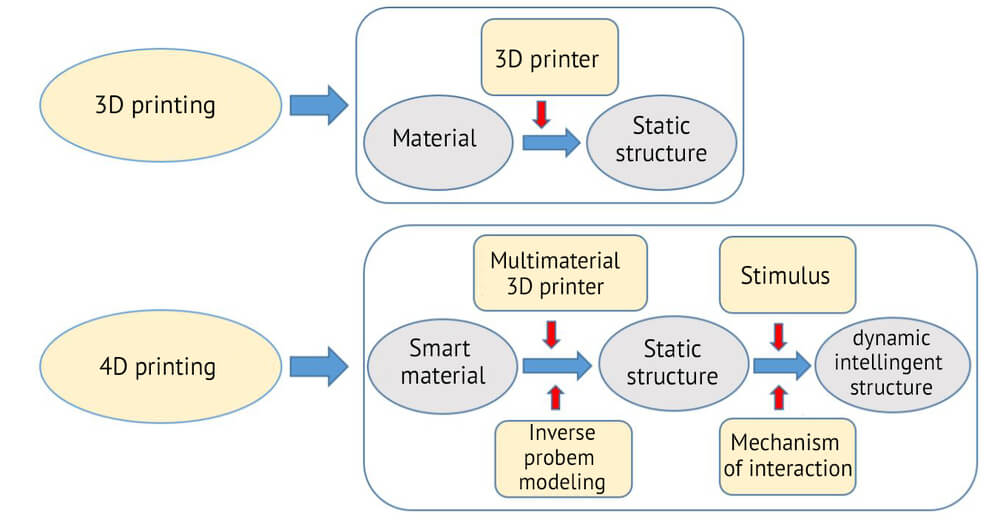

For over three decades, 3D printing was used by the Additive Manufacturers in printing 3D objects rather than 2D images on a one-dimensional plane. Today we will be discussing understanding what 4D printing is and how it can help manufacturers breakthrough with tremendous potential via innovative application of this technology that came to us straight from the future.

Brief Understanding of The Differences of 2D, 3D and 4D Printing Technologies

2D printing is the most common way of printing; to understand this in the most simple manner, imagine you print an assignment or a picture of your favourite movie star on paper that would give you an example of 2D printing. The meaning of 2D printing is, as the name interprets, it prints two-dimensional (with length and breadth) content on paper.

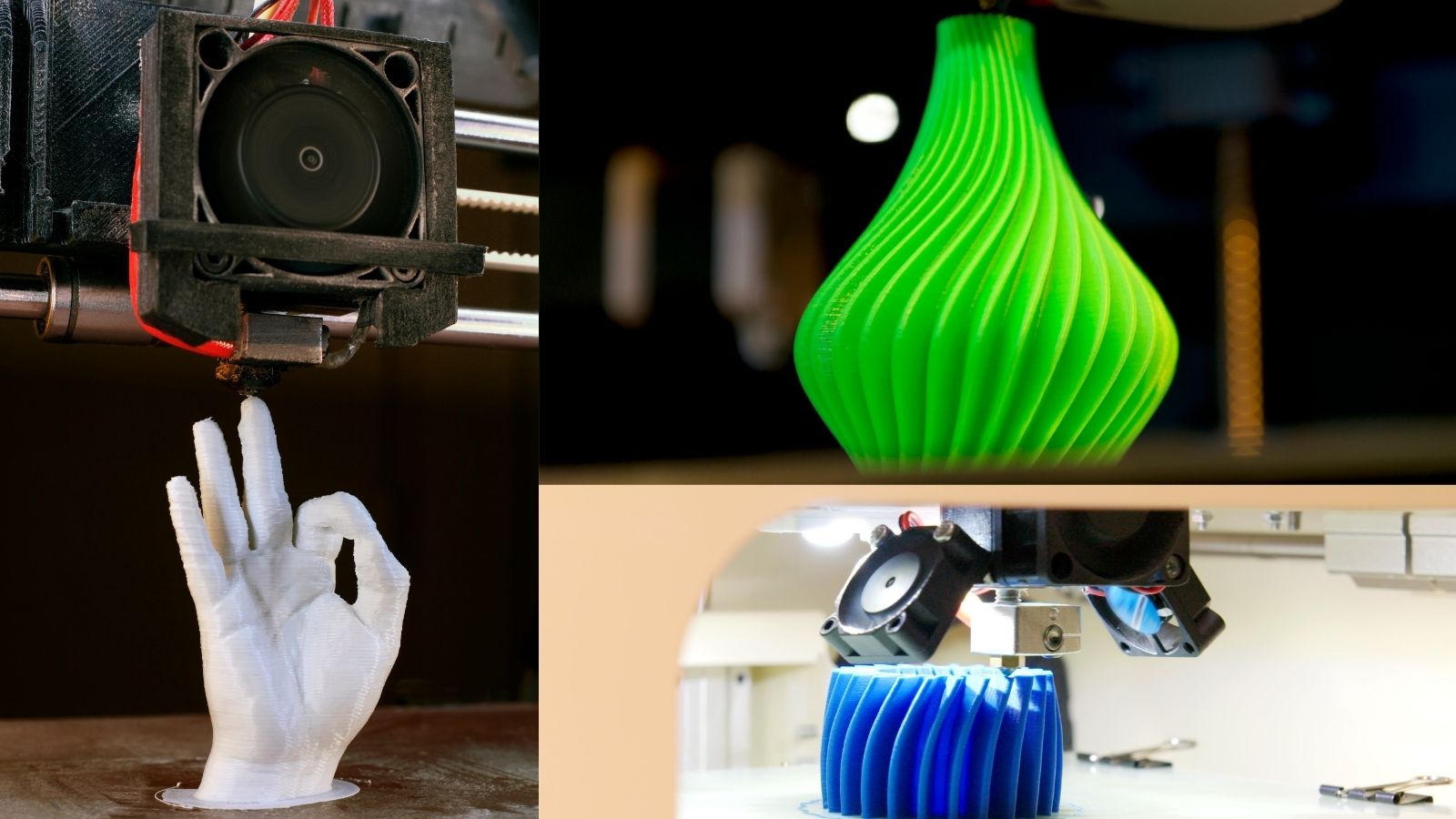

3D printing takes a step ahead by allowing the printable content to take the form of three dimensions- length, breadth and height. It allows the user to print a tangible model that represents a structure developed via a CAD or Digital 3D representation. This technology prints models using material like PLA, ABS and other various blends that allows the model to have properties like resistance to chemicals, heat or impact and rigidity.

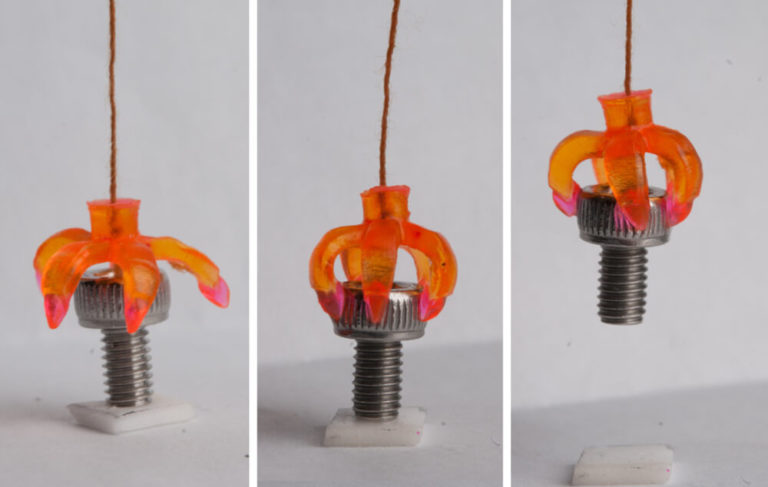

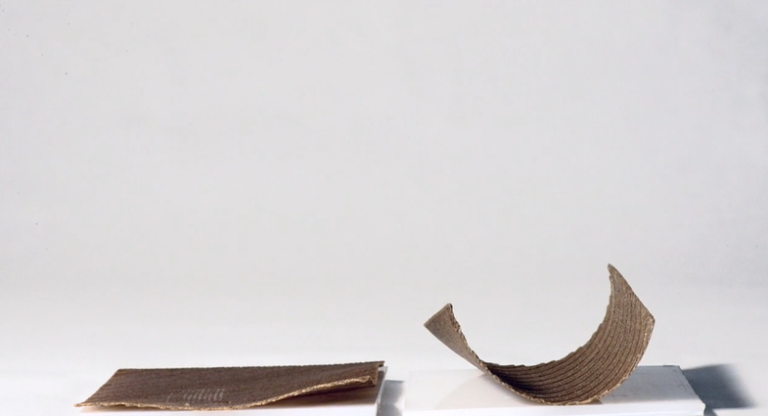

4D printing takes 3D printing to a further step by using commercial printers to print mouldable objects- in other words, 3D models that can be changed when exposed to something like heat, pressure or light or any other environmental stimuli. For example, a 4D-printed gripper is an object that grips onto an object when the temperature is optimal- in other words; it changes its position in response to the temperature. A picture of a 4D-printed gripper is shown below.

A Deeper Understanding About 4D Printing

This technology is applied for a number of amazing and innovative applications. Including:

- Allowing freedom to design anything

- Ameliorate complex assemblies by enhancing production efficiencies

- Enhance personalisation and market growth of the manufacturing sector

- Improve the reliability and performance of industrial assets

- Increasing the responsiveness of the airbags

- Optimising the comfort of car seats

- Smart goods manufacturing like smart plumbing devices, smart water valves and other goods with transformable nature

A Deeper Understanding About 4D Printing

4D Printing for Additive Manufacturing

A multitude of enhancements is spurred by the application of 4D printing technologies in the additive manufacturing field. It allows ameliorated process of building objects that meet the unique purposes of the printed object in terms of shape, flexibility, mouldability, and other structural and functional facets. This technology enables additional SMPS, and expensive 3D processes in the building process and the smart materials are programmed with shape memory-based programming protocols that allow unique printing procedures like thermochemical trained objects or multifaceted material printing.

It enormously cuts down the manufacturing labour cost because it precisely manufactures responsive objects with higher output speeds, better quality and less wastage of energy, time, money and resources- no cutting, skimming or sharpening required. This eliminates the need of relying on processors, onboard cameras or power storage engines. For manufacturing applications of 4D printing are:

- Liquid Solidification

- Material Intrusion

- Material Jetting

- Powder Solidification

Self-repairing Pipe Systems

Pipes in plumbing, storm water, gas, oil, wastewater, and water systems can be developed using 4D technology allowing the pipes to respond to water pressure and dynamically augment the size of the diameters to avoid pipe blocks or breakages. In case of pipe cracks, breaks or waning, the 4D-printed pipes will allow the pipe to “self-heal”. Crazy as it sounds, innovators and 4D specialists do believe that this is one of the most advantageous potentials for researchers to develop smart pipes in the near future.

Furniture with Capabilities to Self-Assemble

4D-based Biomaterial Printing

This technology is engineered nanoparticle therapies that facilitate chemotherapy for cancer patients allowing the damaged tissues to be recovered faster than the average healing process. It is also used to print implants, skin grafts and other hydrogel objects that do not necessarily require external interference to alter their functional or structural nature. So this technology heals, customises appearances and even prints human organs, skin, tissues, links, skeletons, ears and other body parts, allowing it to be an indispensable technology in the medical field.

4D Printing for Space Exploration

The 4D-printed structure foreshadows remarkable advancements in future innovations to facilitate space exploration. This technology can enable first-print-success of parts and structures printed using expensive material; thus reducing the wastage of precious material and time. Here are some of the unique advantages of using 4D printing for space applications.

- Allow the engineers the freedom of designing any type of complex shape without any restrictions

- Being able to mould shapes into more complex geometries when contacted with pre-learned exposures

- High-aspect ratios, lower angles and density of walls can be printed accurately

- Rapid production of millions of identical pieces with ease

- Printing quality can be verified layer by layer

- Lesser costs and lesser wastage of material when printing space-related items and parts

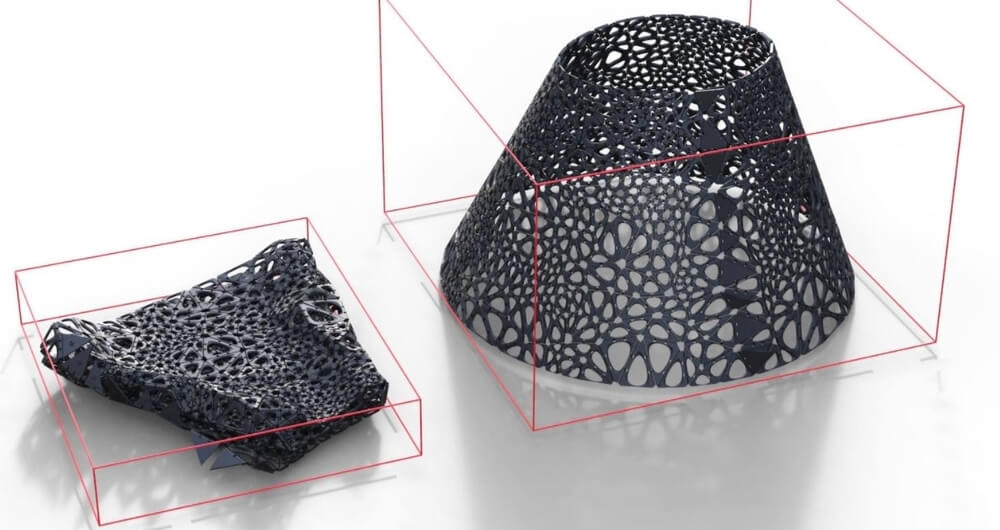

There is a case study where flat-folded space struts engineered with 4D printing can be fully unfurled when they are exposed to a heat of 149-degrees Fahrenheit. This technology also promises that in the future spacecraft engineers can design more complicated structures that take less space in the craft and is elongated, undone or restructured under unique exposures in space, for example, antennas that are compressed being expanded only after reaching a certain temperature from the sun’s heat.

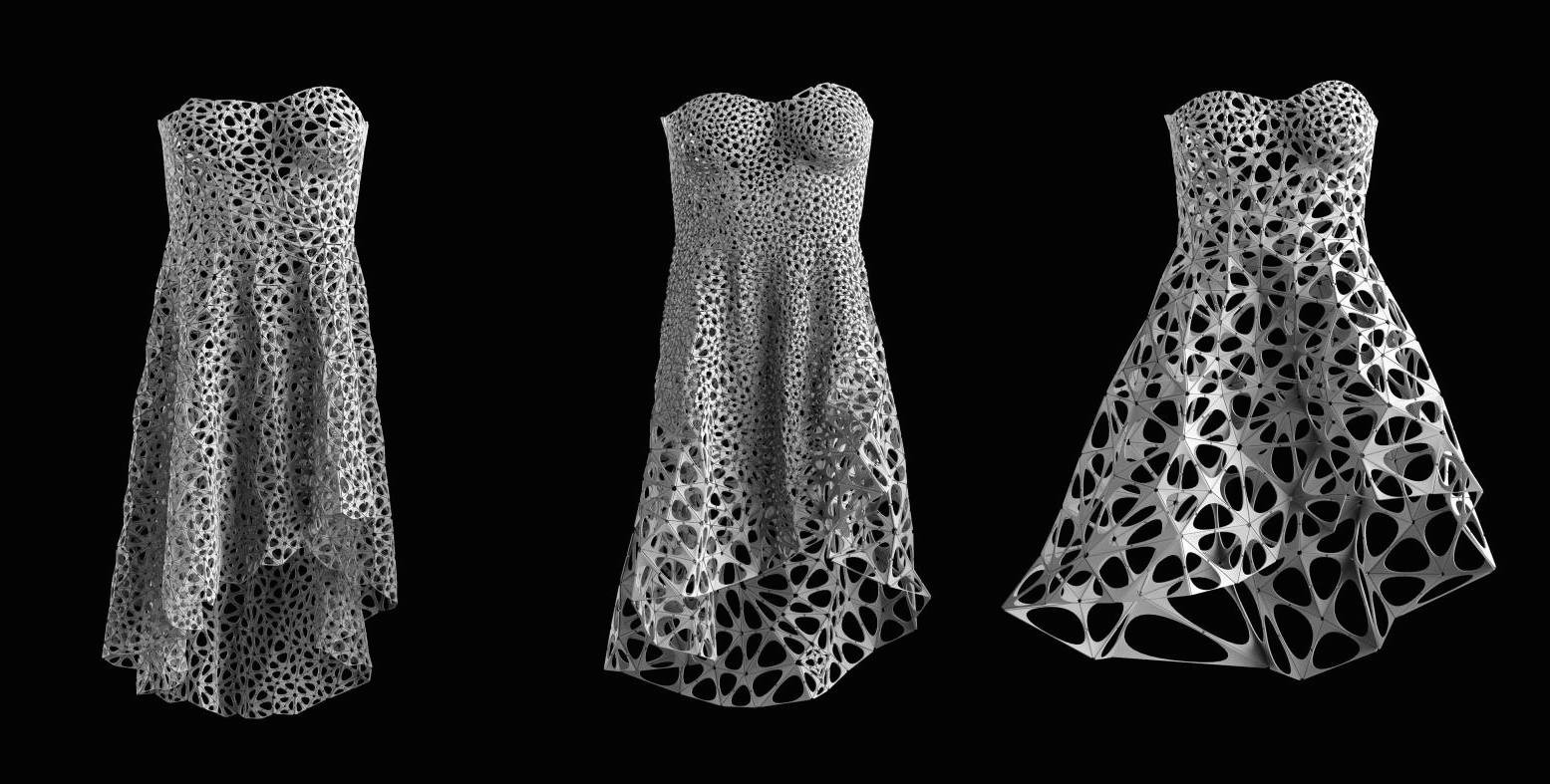

4D Printing for Fashion Apparel

Cerexio and Additive Manufacturing

Cerexio is one of the few innovative technology solution providers to be updated with the recent technologies in the additive manufacturing field. Connect with our innovation experts and field specialists to help you understand more about equipping the latest additive manufacturing technologies in making your establishment a futuristic settlement. We are the most trusted technology solution providers for manufacturing specialists around the world, for we enable all technologies that are defined by the industry 4.0 demands. Connect with Cerexio to learn more about our expertise.