Since you are in the manufacturing business, you know that this is one industry that gives you flexibility in choosing the best strategies for you to proceed with your productions. What type of manufacturing do you think is the most reliable? When you select one of the many of them, you have to consider various facts like the type of your product, the requirements of the clientele, workflow processes, etc. 3D printing has been one of the most popular choices when it comes to the main branches of the industrial world. Do you think it is a good choice for the companies to opt for?

Well, this article is all about that. In this article, we will reveal everything about 3D printing and the reasons why it has become a good option for manufacturers.

We will know

- What is 3D Printing in Manufacturing?

- The Top 4 Reasons Why 3D Printing is a Good Choice in Manufacturing

- On-Demand Production and Inventory Management

- Design Freedom and Iteration

- Reduced Material Waste

- Customisation and Personalisation

- Cerexio Solutions for Manufacturing Excellence

- Opting for 3D Printing as the Ultimate Choice

What is 3D Printing in Manufacturing?

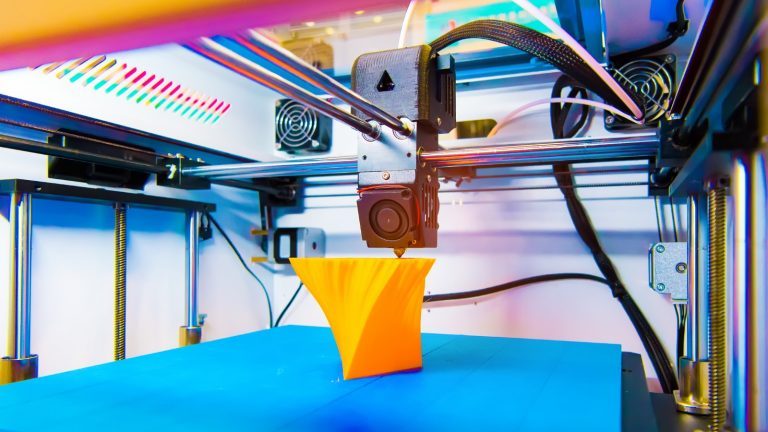

- Before we begin, we need to understand why this has become so popular in the manufacturing domain. 3D printing is one of the manufacturing branches that revolutionises manufacturing processes by constructing three-dimensional objects layer by layer from digital designs.

- Its uniqueness lies in its ability to produce complex geometries with minimal material waste, unlike traditional subtractive methods.

- The main reason for its popularity is due to its prototyping ability. Manufacturers rely on 3D printing for its rapid prototyping capabilities, which allow quick iteration and customisation of designs.

- You know that this has on-demand production capacity. It facilitates just-in-time manufacturing, reducing inventory costs, and enabling decentralised production.

- Furthermore, the ability to create freely and produce prototypes and customised items without the need for costly tooling are two more ways that 3D printing encourages manufacturing creativity.

- In the manufacturing domain alone, its versatility spans various industries, from automotive and aerospace to healthcare and consumer goods, etc. In the modern digital manufacturing realm, 3D Printing has become a vital component of the whole business ecosystem.

The Top 4 Reasons Why 3D Printing is a Good Choice in Manufacturing

On-Demand Production and Inventory Management

We earlier mentioned that flexibility is the most important component when it comes to the manufacturing domain. In a world full of varieties, manufacturing companies will not be able to proceed successfully if they do not adjust to market demand. And, in the sense of customer demands, this indeed varies from time to time.

Therefore, 3D printing’s on-demand production and inventory management capabilities make it an ideal choice in manufacturing by offering flexibility and efficiency.

Unlike traditional manufacturing methods that require mass production and storage of inventory, 3D printing backs up companies to produce items as needed. This certainly reduces excess inventory and associated costs.

This is a just-in-time manufacturing approach, for sure. The latter minimises the risk of overproduction, inventory obsolescence, and storage expenses. Plus, it paves the way to establish decentralised production and allows for localised manufacturing to meet regional demand more effectively. With this ability to quickly adjust production to changing market demands in hands, manufacturers can respond quickly to fluctuations in consumer preferences and reduce lead times.

It is an obvious benefit of on-demand production through 3D Printing. This full-scale inventory management contributes to leaner, more agile manufacturing processes in the end. No need to say that it helps optimise resource utilisation and enhance competitiveness in the Singaporean marketplace.

Design Freedom and Iteration

The number one question that comes to your mind might be, ‘Why do manufacturers require this much freedom to design’? The answer is simple. That is because it allows them to explore innovative concepts and create unique product designs. This makes them different from the competitors in the market. With such freedom in action, manufacturers can easily expand their territory to attract more customer bases.

This is where 3D printing comes in as the best solution. It offers unparalleled design freedom and iteration capabilities, making it a favoured choice in manufacturing.

The days are gone when you relied on traditional methods that were constrained by moulds or tooling. 3D printing allows for the creation of complex geometries and intricate designs with minimal limitations.

This freedom lets manufacturing designers explore innovative concepts and refine designs rapidly. As it encourages quick iteration cycles, the latter accelerates the product development process in the first place. It also reduces time-to-market and enhances competitiveness, for sure.

With this capacity, manufacturing designers can easily incorporate feedback and iterate on prototypes. As you can see, this optimises product functionality and performance. On the other hand, the ability to customise and personalise products on demand further expands design possibilities and market opportunities, as we stated before.

It is evident that this digital capability empowers manufacturers to innovate and adapt to evolving consumer preferences. There is no need to worry about the dynamics or changing proceedings anymore. You can always deliver highly tailored products without compromising their quality now.

Reduced Material Waste

Receiving the optimal yield benefit is a key expectation of manufacturers nowadays. When you implement 3D Printing, it is no longer a challenge.

3D printing has already proven to be beneficial in reducing material waste compared to traditional manufacturing methods.

Unlike subtractive processes that involve cutting away excess material, 3D printing is an additive manufacturing technique that builds objects layer by layer precisely according to digital designs. This method guarantees that just the precise quantity of material required for production gets utilised, reducing waste and maximising the use of available resources.

In addition to saving money, 3D printing minimises environmental effects by minimising material waste, which also helps to meet sustainability objectives. Its eco-friendliness is further improved by the fact that some 3D printing materials may be recycled and used again.

Customisation and Personalisation

Thanks to its unmatched capacity to be customised and personalised, 3D printing is becoming a popular choice in the manufacturing industry.

In those days, manufacturers had to rely on standardised production processes, if you remember. 3D printing revolutionised this whole ecosystem and started allowing for the creation of products tailored to individual needs and preferences.

Its adaptability lets producers satisfy a wide range of consumer needs by providing distinctive product variations without having to shell out a lot of extra money or wait times. Custom-designed consumer items and personalised medical implants are just two examples of individualised solutions that 3D printing enables businesses to provide to their target market.

Due to this capacity, manufacturers can strengthen brand loyalty, build stronger consumer connections, and obtain a competitive advantage in the market.

Cerexio Solutions for Manufacturing Excellence

Cerexio is your ultimate destination in the quest for the best technologies that can streamline your manufacturing operational background. As our robust solutions are highly flexible and customisable, you can easily strengthen your manufacturing procedures by employing them. If you target perfection in every way, Cerexio is the answer for you.

Opting for 3D Printing as the Ultimate Choice

We believe that you understand that 3D Printing is an excellent option if you consider flexibility and scalability to be your biggest challenges in the manufacturing battleground. With this strategy in hand, you can boost the efficiency of your production floor, gain a productivity advantage, offer customisable products to clients, and expand your manufacturing kingdom to an unlimited distance. However, our friendly reminder is to collaborate with a reliable software provider when optimising your 3D Printing operations through new technologies.